Features :

1. Suitable for cleaning large quantities PCBA, online completion of cleaning, rinsing and drying all the processes

2. Excellent cleaning effect, the effective removal of rosin, water soluble flux, disposable flux and other organic, inorganic pollutants

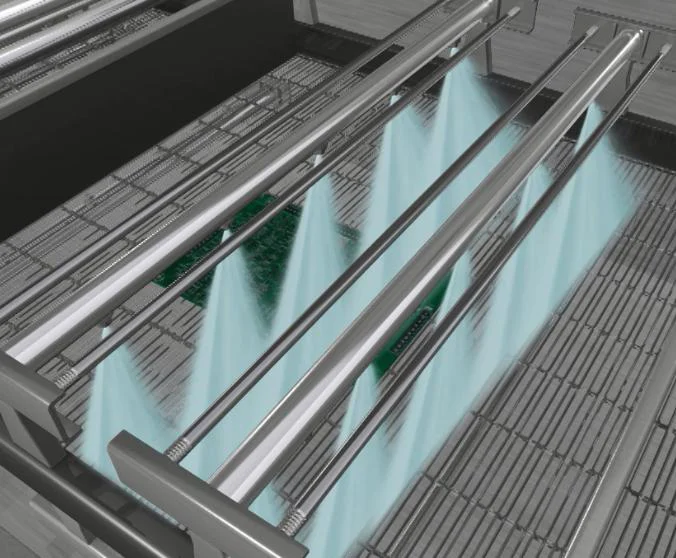

3. Standard process: Pre cleaning---Cleaning---Chemical isolation---Pre rinsing---Wind cut isolation---Rinsing---Rinsing 2---Final spray--- Wind knife 1 cutting water--- Wind knife 2 cutting water --- Hot air drying

4. Excellent chemical isolation, low running costs

5. Stainless steel canbinet with good reliability andcan resisit any hurt by acid and alkali cleaning chemistry.

6. Small plate can be placed PCBA fixture;

7. Resistivity meter monitoring rinsing liquid , ensuring cleanliness

8. Wind knife cutting water+ Infrared hot air circulation

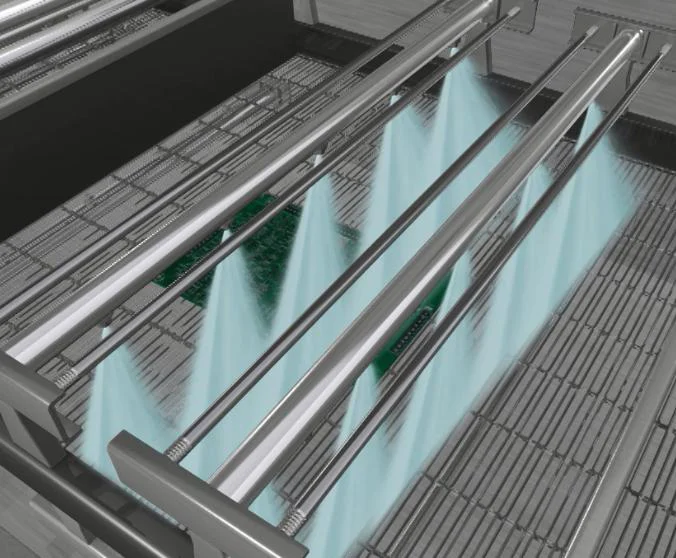

9. Selection of spray cleaning knife, make better cleaning effect;

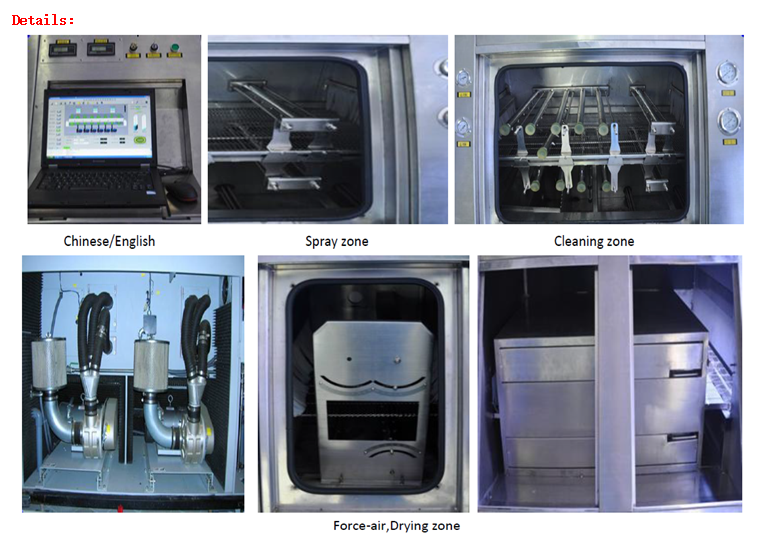

10. 15.6" touch-screen computer automation control, Chinese / English operation interface;

11. Flexible operation of water cleaning or chemical solvent cleaning;

12. The unique rinsing overflow design to save water consumption;

13. UPS standby power supply system;

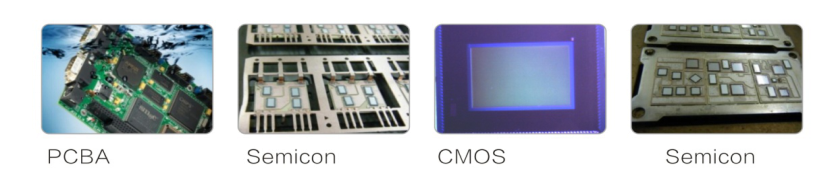

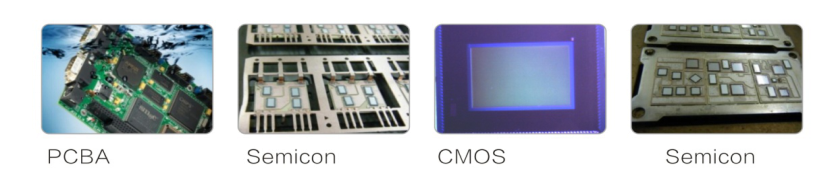

Application

Specification

Board direction : Left to right [Front window view ]

Control mode: using one touch type computer + PLC configuration software control

Speed: 0.1-1.5m / min adjustable;0.8 m / min ( recommended )

Cleaning PCBA Size:Max 600mm(W) × 100mm(H)

Cleaning PCBA Size:Min 50mm(W)×50 mm(H) (To be clamped)

Board Thickness: 0.1~ 4mm

Cleaning Solvent Tank Capability:300L(Max)

Cleaning Pump Power:11KW

Cleaning Solvent Filter:0.45μm

Cleaning Solvent Heating Power:27KW

Rinsing Tank Capacity:180L(Max)

Rinsing Tank Heating Power:36KW

Rinsing Pump Power:11KW

Cleaning Method:high pressure spray

Drying Method:high pressure blower cutting water and Hot air circulation

Drying Heating Power:15KW

Solvent Heating Temperature:RT~70℃

Drying Temperature:RT~100℃

DI Water Consumption:10-15L /Min

DI Water Access Pressure: <0.5Mpa

Resistivity meter monitoring range:0~18 MΩ

Conveyor height:900 ± 50mm

Exhaust volume: 40M³/Min

Power Supply:AC380V 50HZ

Total Power:≈ 136KW

Net Weight:2500Kg

Outlet Size: Φ250mm(W)×50mm(H)*2PCS

Machine Size:6580 mm (L)×1580 mm (W) ×1600 mm (H)

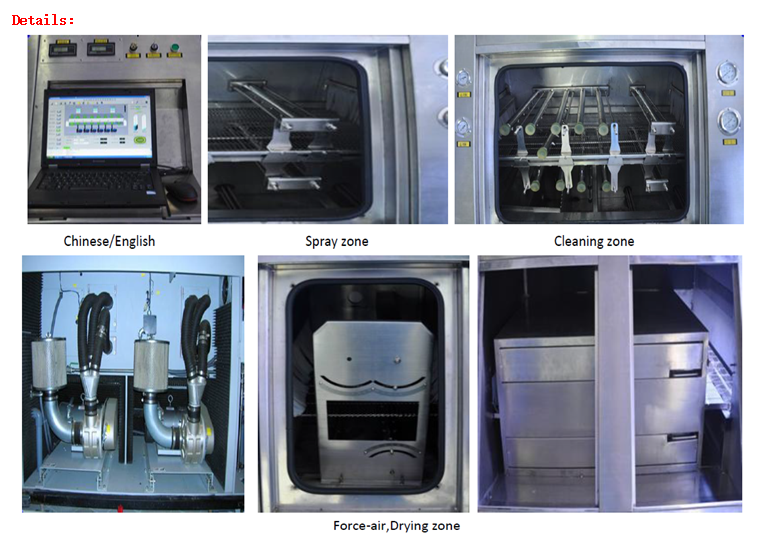

Detail Pictures :

Features :

1. Suitable for cleaning large quantities PCBA, online completion of cleaning, rinsing and drying all the processes

2. Excellent cleaning effect, the effective removal of rosin, water soluble flux, disposable flux and other organic, inorganic pollutants

3. Standard process: Pre cleaning---Cleaning---Chemical isolation---Pre rinsing---Wind cut isolation---Rinsing---Rinsing 2---Final spray--- Wind knife 1 cutting water--- Wind knife 2 cutting water --- Hot air drying

4. Excellent chemical isolation, low running costs

5. Stainless steel canbinet with good reliability andcan resisit any hurt by acid and alkali cleaning chemistry.

6. Small plate can be placed PCBA fixture;

7. Resistivity meter monitoring rinsing liquid , ensuring cleanliness

8. Wind knife cutting water+ Infrared hot air circulation

9. Selection of spray cleaning knife, make better cleaning effect;

10. 15.6" touch-screen computer automation control, Chinese / English operation interface;

11. Flexible operation of water cleaning or chemical solvent cleaning;

12. The unique rinsing overflow design to save water consumption;

13. UPS standby power supply system;

Application

Specification

Board direction : Left to right [Front window view ]

Control mode: using one touch type computer + PLC configuration software control

Speed: 0.1-1.5m / min adjustable;0.8 m / min ( recommended )

Cleaning PCBA Size:Max 600mm(W) × 100mm(H)

Cleaning PCBA Size:Min 50mm(W)×50 mm(H) (To be clamped)

Board Thickness: 0.1~ 4mm

Cleaning Solvent Tank Capability:300L(Max)

Cleaning Pump Power:11KW

Cleaning Solvent Filter:0.45μm

Cleaning Solvent Heating Power:27KW

Rinsing Tank Capacity:180L(Max)

Rinsing Tank Heating Power:36KW

Rinsing Pump Power:11KW

Cleaning Method:high pressure spray

Drying Method:high pressure blower cutting water and Hot air circulation

Drying Heating Power:15KW

Solvent Heating Temperature:RT~70℃

Drying Temperature:RT~100℃

DI Water Consumption:10-15L /Min

DI Water Access Pressure: <0.5Mpa

Resistivity meter monitoring range:0~18 MΩ

Conveyor height:900 ± 50mm

Exhaust volume: 40M³/Min

Power Supply:AC380V 50HZ

Total Power:≈ 136KW

Net Weight:2500Kg

Outlet Size: Φ250mm(W)×50mm(H)*2PCS

Machine Size:6580 mm (L)×1580 mm (W) ×1600 mm (H)

Detail Pictures :

Website:https://www.pcbcuttingmachine.com

Contacts:Eva Liu +8613450659407 +8613416743702

Tel:+86-512-62751429

Skype:evaliuhuan

Email:caojun@hk-yush.com sales@yushunli.com evaliu@hk-yush.com

Address: Building H, GuoRui Pioneering Park,

No. 1068 Jinyang East Road, Lujia Town, Kunshan,Suzhou.

Postcode:215331

Dongguan Factory Address: 5th Floor, No.10,

Shanquan Road, Yongtou Village, Chang’an Town,

Dongguan City, Guangdong province, China.

Postcode:523843