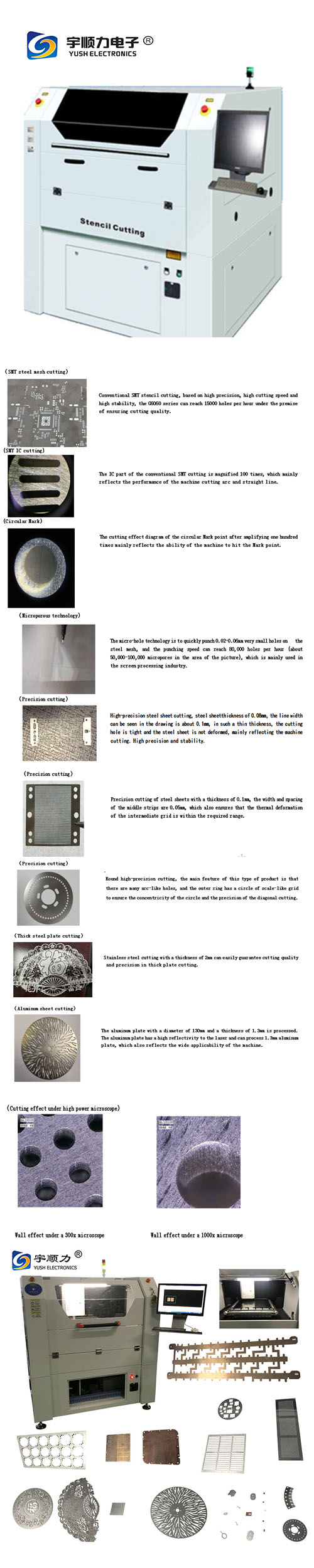

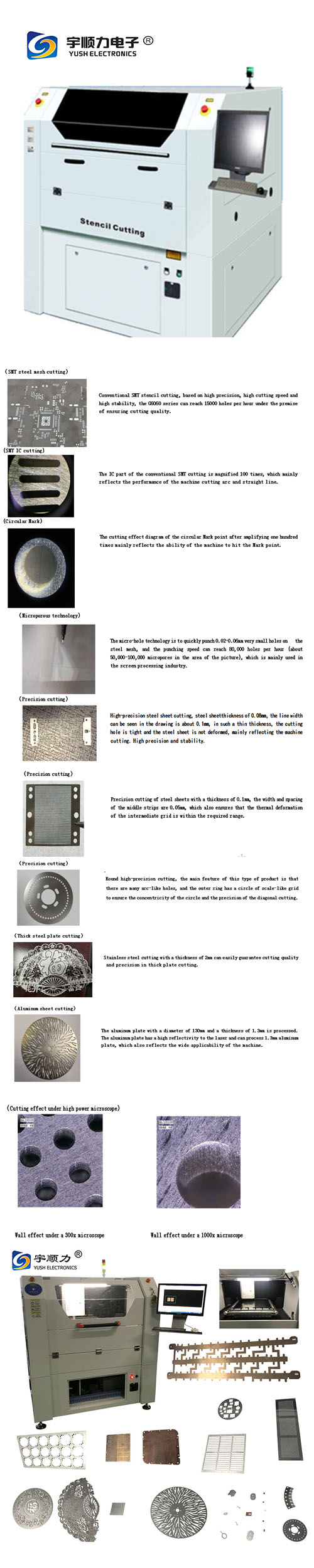

1680*1500*1630mm300mm/S 1200KG 10w laser cutter Sheet metal stencil laser depaneling machine smt cutting equipment

1.Unique waste collection structure

Based on the new structure design, YS-SL6060 uses innovative waste and smoke collection system, which completely frees customers from "equipment stabilization killers" such as chips, slag, iron dust and so on. It greatly improves the service life and stability of the equipment.

2.High Power Fiber Laser

YS-SL6060 is a semiconductor-pumped solid-state high-power fiber laser with advanced technology. Increasing the cutting efficiency also greatly increases the types of Machinable products. It is easy to deal with both ordinary metal sheets and precise parts with a certain thickness.

3.Provide users with specialized process solutions

Professional fixture design, can adapt to a variety of sizes, shapes of materials, so that every minute of production belongs to laser cutting. This is not only a device, but also a set of equipment process system that can optimize the user's process and give full play to the maximum value of the equipment.

Equipment description.

1. Machine Name :High-speed laser sheet metal cutting machines .

2. Model: YS-SL6060 .

3. Applications : SMT templates, precision metal parts.

4. Equipment Properties :

| Machine color | creamy-white |

| Total Weight | About 1500KG . |

| physical dimension | L1680*W1500*H1630mm |

| Platform | Granite base, with high stability and reliability. |

| Total power | Rated :2KW. Peak 6KW. |

|

Power system requirements |

Provide the regulator (AC 220V and single-phase 10KVA), in order to ensure to the power supply voltage fluctuations device does not exceed ± 5%. |

| Grounding Requirements | Provide independent and stable ground without loopholes interference. Ground line is: 6MM² |

|

Environmental requirements |

Offer supply of pure oxygen, the non-oil and gas and water vapor mixed, to avoid damaging optics. Ensure that equipment using ambient room temperature 24-26 ℃, and relative humidity below 60 ° indoor use. Clean environment. |

5. Technical specifications.

| Platform positioning accuracy |

±3μm |

| Platform Repeatability | ±1.5μm |

| Platform velocity | ≤300mm/S |

| Location detection sub variability |

0.1μm |

| Cutting range | X 600mm * Y 600MM |

| Table size | X 620mm * Y 620MM |

| Cutting thickness | ≤0.5mm (reference value) |

| Focus diameter | 25-30μm |

|

Best Cutting Effectiveness |

Up to 9400 Synthetic Aperture / hr, 13000-14000 standard aperture / hour (with a diameter of 0.3mm standard round date). Scope is 0.15mm less steel). |

6. Configuration Specification.

| Laser light source Specifications | |

| Laser Power | 50W |

| Wavelength | 1070 mm |

| Laser Weight | About 20KG |

| Beam delivery system | |

| Dust-proof | Dust Cover |

| Control and drive systems | |

| Control | PC-BASE CNC AC Servo Control |

| Drive | Linear motor drive |

| Guide | Precision linear guide rails |

| Others | |

| CCD module | CCD fill holes focus, coaxial CCD light function. |

| Dust | Collect waste and zero-emission. |

| Blowing | Coaxial blow assist gas. |

| Fixture | Pneumatic clamping |

7.Software system .

| Software system | YUSH Mark |

| Language | Chinese/ English |

|

Application Environment |

Windows XP |

| File format | DXF ,CNC |

|

Implementation monitoring |

Cutting time, cutting the number of holes, the auxiliary gas, cutting state. |

|

Software Features |

1. CNC support directly open documents, DXF file, Gerber file and drawing were selected, rotate, mirror and other operations. 2. Support the establishment of different cutting parameters for different databases steel thickness stee 3. Support for documents path optimization. 4. supports automatic cutting member cutting case records to the query. |

1680*1500*1630mm300mm/S 1200KG 10w laser cutter Sheet metal stencil laser depaneling machine smt cutting equipment

1.Unique waste collection structure

Based on the new structure design, YS-SL6060 uses innovative waste and smoke collection system, which completely frees customers from "equipment stabilization killers" such as chips, slag, iron dust and so on. It greatly improves the service life and stability of the equipment.

2.High Power Fiber Laser

YS-SL6060 is a semiconductor-pumped solid-state high-power fiber laser with advanced technology. Increasing the cutting efficiency also greatly increases the types of Machinable products. It is easy to deal with both ordinary metal sheets and precise parts with a certain thickness.

3.Provide users with specialized process solutions

Professional fixture design, can adapt to a variety of sizes, shapes of materials, so that every minute of production belongs to laser cutting. This is not only a device, but also a set of equipment process system that can optimize the user's process and give full play to the maximum value of the equipment.

Equipment description.

1. Machine Name :High-speed laser sheet metal cutting machines .

2. Model: YS-SL6060 .

3. Applications : SMT templates, precision metal parts.

4. Equipment Properties :

| Machine color | creamy-white |

| Total Weight | About 1500KG . |

| physical dimension | L1680*W1500*H1630mm |

| Platform | Granite base, with high stability and reliability. |

| Total power | Rated :2KW. Peak 6KW. |

|

Power system requirements |

Provide the regulator (AC 220V and single-phase 10KVA), in order to ensure to the power supply voltage fluctuations device does not exceed ± 5%. |

| Grounding Requirements | Provide independent and stable ground without loopholes interference. Ground line is: 6MM² |

|

Environmental requirements |

Offer supply of pure oxygen, the non-oil and gas and water vapor mixed, to avoid damaging optics. Ensure that equipment using ambient room temperature 24-26 ℃, and relative humidity below 60 ° indoor use. Clean environment. |

5. Technical specifications.

| Platform positioning accuracy |

±3μm |

| Platform Repeatability | ±1.5μm |

| Platform velocity | ≤300mm/S |

| Location detection sub variability |

0.1μm |

| Cutting range | X 600mm * Y 600MM |

| Table size | X 620mm * Y 620MM |

| Cutting thickness | ≤0.5mm (reference value) |

| Focus diameter | 25-30μm |

|

Best Cutting Effectiveness |

Up to 9400 Synthetic Aperture / hr, 13000-14000 standard aperture / hour (with a diameter of 0.3mm standard round date). Scope is 0.15mm less steel). |

6. Configuration Specification.

| Laser light source Specifications | |

| Laser Power | 50W |

| Wavelength | 1070 mm |

| Laser Weight | About 20KG |

| Beam delivery system | |

| Dust-proof | Dust Cover |

| Control and drive systems | |

| Control | PC-BASE CNC AC Servo Control |

| Drive | Linear motor drive |

| Guide | Precision linear guide rails |

| Others | |

| CCD module | CCD fill holes focus, coaxial CCD light function. |

| Dust | Collect waste and zero-emission. |

| Blowing | Coaxial blow assist gas. |

| Fixture | Pneumatic clamping |

7.Software system .

| Software system | YUSH Mark |

| Language | Chinese/ English |

|

Application Environment |

Windows XP |

| File format | DXF ,CNC |

|

Implementation monitoring |

Cutting time, cutting the number of holes, the auxiliary gas, cutting state. |

|

Software Features |

1. CNC support directly open documents, DXF file, Gerber file and drawing were selected, rotate, mirror and other operations. 2. Support the establishment of different cutting parameters for different databases steel thickness stee 3. Support for documents path optimization. 4. supports automatic cutting member cutting case records to the query. |

Website:https://www.pcbcuttingmachine.com

Contacts:Eva Liu +8613450659407 +8613416743702

Tel:+86-512-62751429

Skype:evaliuhuan

Email:caojun@hk-yush.com sales@yushunli.com evaliu@hk-yush.com

Address: Building H, GuoRui Pioneering Park,

No. 1068 Jinyang East Road, Lujia Town, Kunshan,Suzhou.

Postcode:215331

Dongguan Factory Address: 5th Floor, No.10,

Shanquan Road, Yongtou Village, Chang’an Town,

Dongguan City, Guangdong province, China.

Postcode:523843