Basic Description

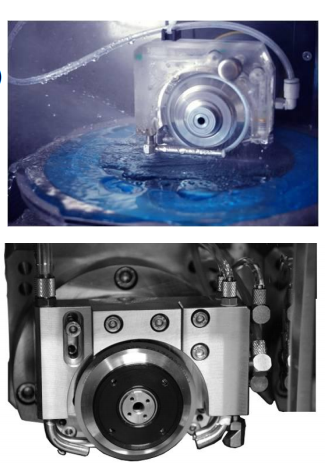

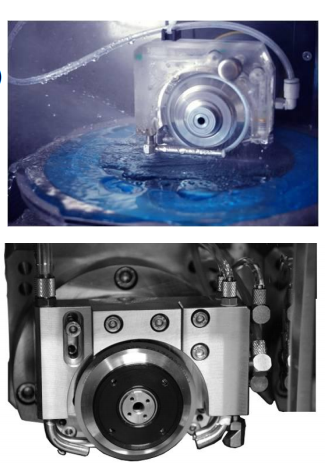

The dicing system, refers to install a slim blade for special cutting at the head of the spindle,cut off glass, ceramic, semiconductor chip, PCB, EMC wire frame and other materials with high accuracy by using spindle’s high-speed rotation driving the cutting blade.

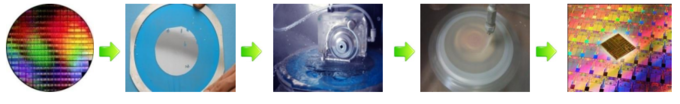

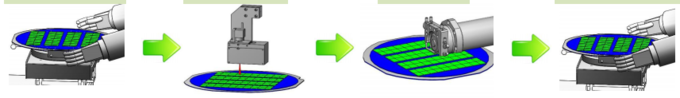

Operation procedures

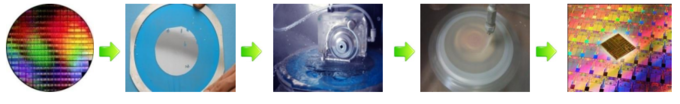

Wafer or Strip Tape mounting Dicing Cleaning UV seperation

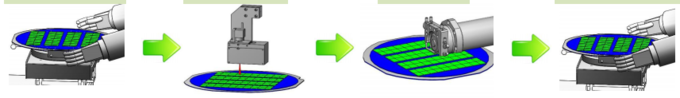

Description of Semi-auto dicing

The semi-auto dicing system, refers to a dicing system that loader and unloader by hand and only the procedure is automated in the process of dicing. The system is not equipped with automatic cleaning, drying, etc.

Main procedures

Feeding by hand Position align Auto-cutting Unloading by hand

1.Operator manually place the material being cut on work platform.

2.The cutting position is automatically calibrated.

3.Press the start button to automatically complete the dicing process of material.

4.Operator take the material manually being cut from the work platform.

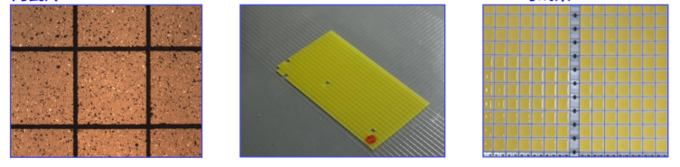

Applications

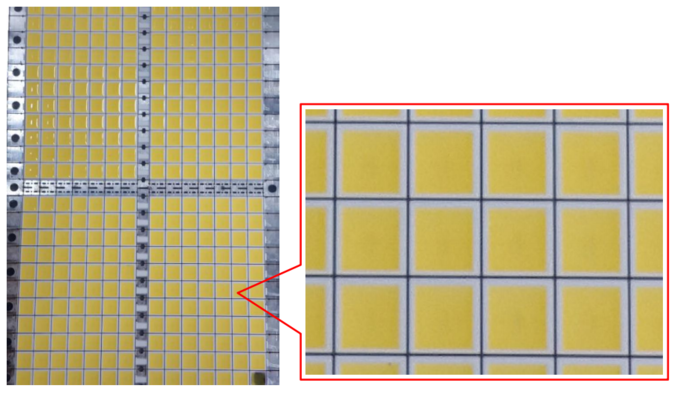

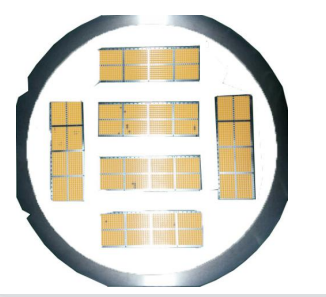

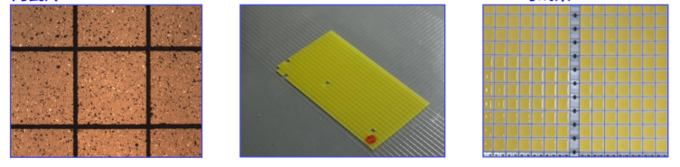

Automatic dicing system is widely used in semiconductor chip, LED chip and EMC lead frame, PCB, IR filter, sapphire glass and ceramic thin plate’s precision cutting .

Ceramic substrate Silicon rubber Lead frame

Silicon wafer PCB Glass

Operating Requirements

1.Please use the clean compressed air that its atmospheric pressure dew point is in the -10 ~ -20℃, and the residual oil is divided into 0.1ppm, the filtering accuracy is above 0.01um/99.5%.

2.Please use the equipment in a room of temperature between 20 ~ 25 ℃, and its fluctuation range control at ±1℃.

3.Please control the temperature of the cutting water at 22 ~ 27 ℃(variation ranges in ±1℃ ), the cooling water at 20 ~ 25 DEG C (variation ranges within plus or ±1℃).

4.Please avoid the equipment to be impacted and any vibration of the outside world. In addition, please do not install the equipment near the device like blower and vent that produces a high temperature and a device that generates oil mist.

5.Please avoid the equipment to be impacted and any vibration of the outside world. In addition, please do not install the equipment near the device like blower and vent that produces a high temperature and a device that generates oil mist.

6.Please follow the product manual we provided for operation strictly.

Semi-dicing system YSL-1000SD Features of products

1.Using touching LCD to operate. The interface design is simple and easy. Provide a variety of languages such as Chinese, English, Korean, etc.

2.Can meet the high precision cutting maximum diameter of 300 mm materials.

3.High rigidity structure design is adopted to ensure high precision and high stability of cutting process.

4.CCD automatic align.

5.Real-time monitoring of the system's air pressure, water pressure, current and other values to avoid spindle damage.

6.Cutting Spindle : 2.4 kw × 1set (Max: 60,000 rpm)

7.Repeat positioning accuracy: 0.001mm

8.Cutting speed: 0.05 ~ 400 mm/sec

9.Standard matching blade: 2 Inch (Max: 3 Inch)

Case Sharing

| System compositionproject | Unit | Specification | |

| Dimensions of processing | mm | Φ300 | |

| Dimensions of working platform | mm | Φ350 | |

| X-axis | Working stroke | mm | 340 |

| Cutting speed | mm/sec | 0.05 ~ 400 | |

| Resolution | mm | 0.0001 | |

| Y-axis | Working stroke | mm | 310 |

| Resolution | mm | 0.0001 | |

| Repeat positioning accuracy | mm | 0.001 / 310 | |

| Z-axis | Working stroke | mm | 60 (2 Inch blade) |

| Resolution | mm | 0.0001 | |

| Θ-axis | Angle of rotation | Deg | 360 |

| Spindle | Power | KW | 2.4 |

| Speed | Rpm | 5000 ~ 60000 | |

| Machine’s specifications | Power supply | V | 3P 220 (50 ~ 60 Hz) |

| Machine power | KW | 4 | |

| Power air pressure | MPa | 0.5 ~ 0.6 | |

| Air consumption | L/min | 200 | |

| Cutting water consumption | L/min | 4 | |

| Cooling water consumption | L/min | 1.5 | |

| Physical dimension | mm | 1040×1080×1750 | |

| Machine net weight | KG | 850 | |

Other Discription

Optional equipment

1.Function of blade damage detection;

2.Automatic setting function;

3.Dicing visual function;

4. Using dicing blade with 3 Inch.

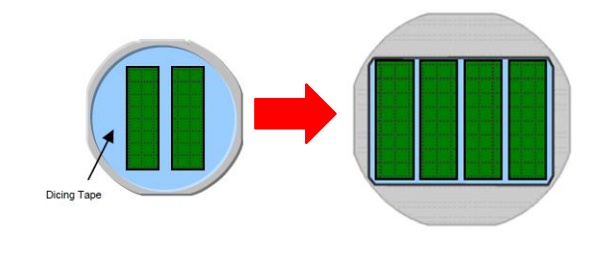

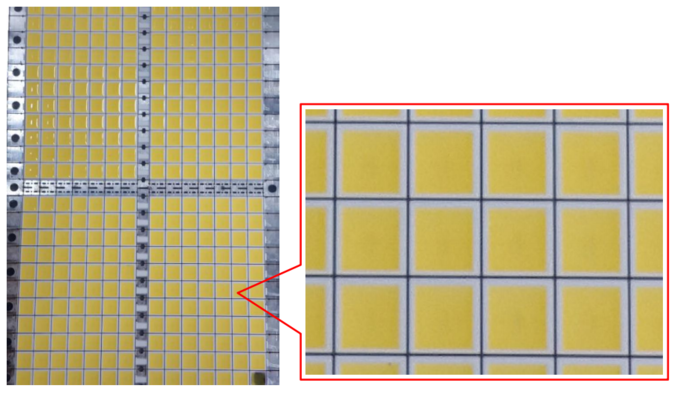

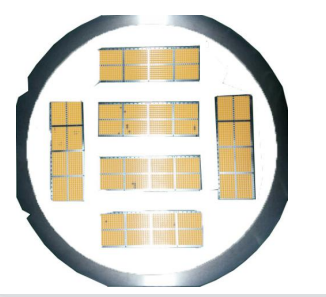

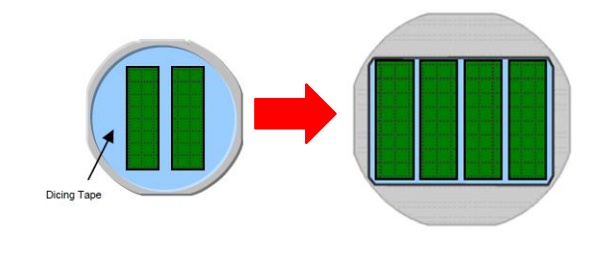

Ordinary 8 inch working platform can only put 2pcs material.

SDS1000/ADS2000 equipped with 12 inch chunk. It can be placed 4pcs material each time.

1.Reduce the loading times;

2.Meet the larger size of the product;

3.Promote more than 8% efficiency.

Basic Description

The dicing system, refers to install a slim blade for special cutting at the head of the spindle,cut off glass, ceramic, semiconductor chip, PCB, EMC wire frame and other materials with high accuracy by using spindle’s high-speed rotation driving the cutting blade.

Operation procedures

Wafer or Strip Tape mounting Dicing Cleaning UV seperation

Description of Semi-auto dicing

The semi-auto dicing system, refers to a dicing system that loader and unloader by hand and only the procedure is automated in the process of dicing. The system is not equipped with automatic cleaning, drying, etc.

Main procedures

Feeding by hand Position align Auto-cutting Unloading by hand

1.Operator manually place the material being cut on work platform.

2.The cutting position is automatically calibrated.

3.Press the start button to automatically complete the dicing process of material.

4.Operator take the material manually being cut from the work platform.

Applications

Automatic dicing system is widely used in semiconductor chip, LED chip and EMC lead frame, PCB, IR filter, sapphire glass and ceramic thin plate’s precision cutting .

Ceramic substrate Silicon rubber Lead frame

Silicon wafer PCB Glass

Operating Requirements

1.Please use the clean compressed air that its atmospheric pressure dew point is in the -10 ~ -20℃, and the residual oil is divided into 0.1ppm, the filtering accuracy is above 0.01um/99.5%.

2.Please use the equipment in a room of temperature between 20 ~ 25 ℃, and its fluctuation range control at ±1℃.

3.Please control the temperature of the cutting water at 22 ~ 27 ℃(variation ranges in ±1℃ ), the cooling water at 20 ~ 25 DEG C (variation ranges within plus or ±1℃).

4.Please avoid the equipment to be impacted and any vibration of the outside world. In addition, please do not install the equipment near the device like blower and vent that produces a high temperature and a device that generates oil mist.

5.Please avoid the equipment to be impacted and any vibration of the outside world. In addition, please do not install the equipment near the device like blower and vent that produces a high temperature and a device that generates oil mist.

6.Please follow the product manual we provided for operation strictly.

Semi-dicing system YSL-1000SD Features of products

1.Using touching LCD to operate. The interface design is simple and easy. Provide a variety of languages such as Chinese, English, Korean, etc.

2.Can meet the high precision cutting maximum diameter of 300 mm materials.

3.High rigidity structure design is adopted to ensure high precision and high stability of cutting process.

4.CCD automatic align.

5.Real-time monitoring of the system's air pressure, water pressure, current and other values to avoid spindle damage.

6.Cutting Spindle : 2.4 kw × 1set (Max: 60,000 rpm)

7.Repeat positioning accuracy: 0.001mm

8.Cutting speed: 0.05 ~ 400 mm/sec

9.Standard matching blade: 2 Inch (Max: 3 Inch)

Case Sharing

| System compositionproject | Unit | Specification | |

| Dimensions of processing | mm | Φ300 | |

| Dimensions of working platform | mm | Φ350 | |

| X-axis | Working stroke | mm | 340 |

| Cutting speed | mm/sec | 0.05 ~ 400 | |

| Resolution | mm | 0.0001 | |

| Y-axis | Working stroke | mm | 310 |

| Resolution | mm | 0.0001 | |

| Repeat positioning accuracy | mm | 0.001 / 310 | |

| Z-axis | Working stroke | mm | 60 (2 Inch blade) |

| Resolution | mm | 0.0001 | |

| Θ-axis | Angle of rotation | Deg | 360 |

| Spindle | Power | KW | 2.4 |

| Speed | Rpm | 5000 ~ 60000 | |

| Machine’s specifications | Power supply | V | 3P 220 (50 ~ 60 Hz) |

| Machine power | KW | 4 | |

| Power air pressure | MPa | 0.5 ~ 0.6 | |

| Air consumption | L/min | 200 | |

| Cutting water consumption | L/min | 4 | |

| Cooling water consumption | L/min | 1.5 | |

| Physical dimension | mm | 1040×1080×1750 | |

| Machine net weight | KG | 850 | |

Other Discription

Optional equipment

1.Function of blade damage detection;

2.Automatic setting function;

3.Dicing visual function;

4. Using dicing blade with 3 Inch.

Ordinary 8 inch working platform can only put 2pcs material.

SDS1000/ADS2000 equipped with 12 inch chunk. It can be placed 4pcs material each time.

1.Reduce the loading times;

2.Meet the larger size of the product;

3.Promote more than 8% efficiency.

Website:https://www.pcbcuttingmachine.com

Contacts:Eva Liu +8613450659407 +8613416743702

Tel:+86-512-62751429

Skype:evaliuhuan

Email:caojun@hk-yush.com sales@yushunli.com evaliu@hk-yush.com

Address: Building H, GuoRui Pioneering Park,

No. 1068 Jinyang East Road, Lujia Town, Kunshan,Suzhou.

Postcode:215331

Dongguan Factory Address: 5th Floor, No.10,

Shanquan Road, Yongtou Village, Chang’an Town,

Dongguan City, Guangdong province, China.

Postcode:523843