Five Features

1.External spraying unit: eliminate safety risks, easy maintenance.

2.Preheating system: adopts high energy efficiency motor with high thermal efficiency.

3.Conveying system: adopts special design for smooth conveying and prevent finger shaking.

4.Exhausting system of spraying: adopts upper and lower exhausting and air knife for separating, to eliminate odor overflow.

5.Exhausting hood system: with high exhausting efficiency, anti foreign matter dripping design can be added , to eliminate quality trouble.

External spraying unit(option:selective spraying system)

Top exhausting and filtering System

Forced cooling system

Lead-free processing nozzle

Flexible combination of preheating system

Heavy-duty conveying system

1.Conveying system: Direct buffering structure.Special stainless steel chain conveying aluminum alloy rail unique design, durable;Transportation system: adopt segmental floating structure, effectively prevent guide rail deformation;

2.Preheating system: Adopts drawer type module with energy-saving design, infrared, hot air convection for any combination, PID temperature control mode, so that the temperature control accuracy reaches to be ±2℃, preheating area and soldering area temperature drop value ≤5℃;

3.Adopt precision control valve for digital regulation, convenient management. Nozzle movement is controlled by stepping motor.Flux automatic pressure supply, which makes the spray flow quickly reach saturation, top exhausting and filtration system;

4.The solder pot is made by cast iron with anti-corrosion ceramic coating equipped with two low flow rate nozzles.

5.Air cooling system: cooling rate 4-6 ℃ /s (adjustable).

6.PC+PLC control system. Windows7 operation system with Chinese/English operation interface. Processing profile and data auto saving function.Alarm for detecting the flux and solder level.

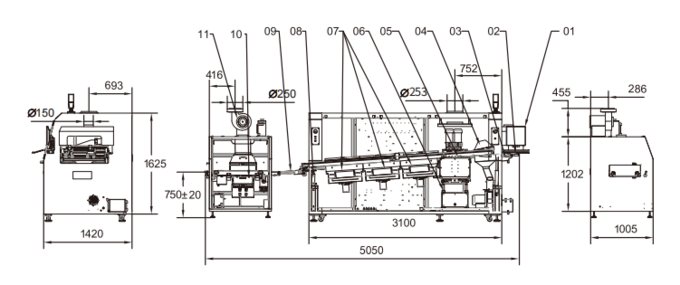

01 LCD

02 Conveyor system

03 Finger cleaning system

04 Cooling system

05 Dual wave solder pot

06 Solder pot lifting unit

07 Pre-heater

08 Angle adjustment controller

09 Buffer system

10 Finger spraying system

11 Exhaust fan

| Model No. | YSL-F | YSL-450F | YSL-610F |

| Dimension: L*W*H(mm) | 5050*1420*1750 | 5050*1520*1750 | 5050*1690*1750 |

| Weight | Approx.1850kg | Approx.2050kg | Approx.2300k |

| Power Supply | 3PH 380V 50HZ | 3PH 380V 50HZ | 3PH 380V 50HZ |

| Start up Power | 33KW | 33KW | 45KW |

| Normal Running Power | Approx.8KW | Approx.9KW | Approx.11KW |

| Control System | PC+PLC | ||

| Spraying movement | Step motor | ||

| Spraying Pressure | 0.2Mpa~0.4Mpa | ||

| Flux Flow Control | Option | ||

| Auto Flux Filling | Standard | ||

| Exhausting | Top exhaust | ||

| Exhausting Pipe Diameter(mm) | Φ250 | ||

| Exhaust fan power | 750W | ||

| Preheating Mode | Hot air convection/IR | ||

| Temperature Control Mode | PID | ||

| Preheating Zone Quantity | 3 | ||

| Preheating Zone Length(mm) | 1800 | ||

| Preheating Temperature Range | Room temperature~200℃ | ||

| Warm-up Time(min) | Approx.12min(setting: 150℃) | ||

| Preheating Blower Motor | 150W 3PH 220 VAC | ||

| Width(mm) | 50~350 | 50~450 | 50~610 |

| PCB Conveying Direction | L→R( Option:R→L) | ||

| Conveying Speed(mm/min) | 500~1800 | ||

| Conveying Height(mm) | 750±20 | ||

| Available Component Height(mm) | Top120 Bottom15 | ||

| Conveying Speed Control Mode | Closed loop stepless speed regulation by inverter | ||

| Finger | Spring Pressing Finger;D-40 Type Finger;Double-hook Finger;Heavy type double hook finger(Options) | Heavy type double hook finge | |

| Option:Special jig for fixture | |||

| Conveying Angle | 4~7° | ||

| Solder Pot Type | Mechanical | ||

| Solder Pot Material | Casting Iron | ||

| Wave Height Adjustment | Inverter: Digital Control by PC | ||

| Cooling type | Air Cooling Option: Water cooling | ||

| Solder Pot Heating Power | 13.5KW | 18KW | |

| Max Solder Pot Temperature | 300℃ | ||

| Solder Pot Capacity | Approx.480kg | Approx.550kg | Approx.640kg |

| Wave Driving Power | 180W*2 3PH 220 VAC | ||

| Solder Pot Warm-up Time | Approx.150min(setting: 250℃) | ||

| Temperature Control Mode | PID | ||

| Finger Cleaning System | Brush | ||

Note:4 sections of preheating can be customized,and the length is 2.3m

Five Features

1.External spraying unit: eliminate safety risks, easy maintenance.

2.Preheating system: adopts high energy efficiency motor with high thermal efficiency.

3.Conveying system: adopts special design for smooth conveying and prevent finger shaking.

4.Exhausting system of spraying: adopts upper and lower exhausting and air knife for separating, to eliminate odor overflow.

5.Exhausting hood system: with high exhausting efficiency, anti foreign matter dripping design can be added , to eliminate quality trouble.

External spraying unit(option:selective spraying system)

Top exhausting and filtering System

Forced cooling system

Lead-free processing nozzle

Flexible combination of preheating system

Heavy-duty conveying system

1.Conveying system: Direct buffering structure.Special stainless steel chain conveying aluminum alloy rail unique design, durable;Transportation system: adopt segmental floating structure, effectively prevent guide rail deformation;

2.Preheating system: Adopts drawer type module with energy-saving design, infrared, hot air convection for any combination, PID temperature control mode, so that the temperature control accuracy reaches to be ±2℃, preheating area and soldering area temperature drop value ≤5℃;

3.Adopt precision control valve for digital regulation, convenient management. Nozzle movement is controlled by stepping motor.Flux automatic pressure supply, which makes the spray flow quickly reach saturation, top exhausting and filtration system;

4.The solder pot is made by cast iron with anti-corrosion ceramic coating equipped with two low flow rate nozzles.

5.Air cooling system: cooling rate 4-6 ℃ /s (adjustable).

6.PC+PLC control system. Windows7 operation system with Chinese/English operation interface. Processing profile and data auto saving function.Alarm for detecting the flux and solder level.

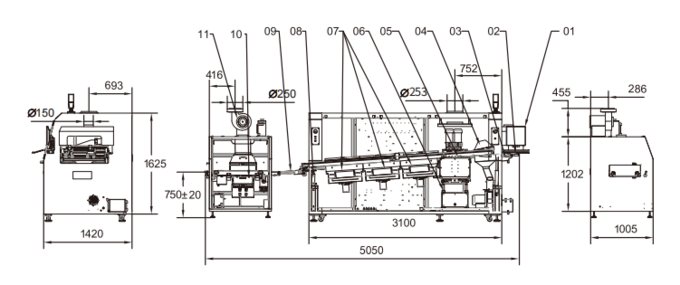

01 LCD

02 Conveyor system

03 Finger cleaning system

04 Cooling system

05 Dual wave solder pot

06 Solder pot lifting unit

07 Pre-heater

08 Angle adjustment controller

09 Buffer system

10 Finger spraying system

11 Exhaust fan

| Model No. | YSL-F | YSL-450F | YSL-610F |

| Dimension: L*W*H(mm) | 5050*1420*1750 | 5050*1520*1750 | 5050*1690*1750 |

| Weight | Approx.1850kg | Approx.2050kg | Approx.2300k |

| Power Supply | 3PH 380V 50HZ | 3PH 380V 50HZ | 3PH 380V 50HZ |

| Start up Power | 33KW | 33KW | 45KW |

| Normal Running Power | Approx.8KW | Approx.9KW | Approx.11KW |

| Control System | PC+PLC | ||

| Spraying movement | Step motor | ||

| Spraying Pressure | 0.2Mpa~0.4Mpa | ||

| Flux Flow Control | Option | ||

| Auto Flux Filling | Standard | ||

| Exhausting | Top exhaust | ||

| Exhausting Pipe Diameter(mm) | Φ250 | ||

| Exhaust fan power | 750W | ||

| Preheating Mode | Hot air convection/IR | ||

| Temperature Control Mode | PID | ||

| Preheating Zone Quantity | 3 | ||

| Preheating Zone Length(mm) | 1800 | ||

| Preheating Temperature Range | Room temperature~200℃ | ||

| Warm-up Time(min) | Approx.12min(setting: 150℃) | ||

| Preheating Blower Motor | 150W 3PH 220 VAC | ||

| Width(mm) | 50~350 | 50~450 | 50~610 |

| PCB Conveying Direction | L→R( Option:R→L) | ||

| Conveying Speed(mm/min) | 500~1800 | ||

| Conveying Height(mm) | 750±20 | ||

| Available Component Height(mm) | Top120 Bottom15 | ||

| Conveying Speed Control Mode | Closed loop stepless speed regulation by inverter | ||

| Finger | Spring Pressing Finger;D-40 Type Finger;Double-hook Finger;Heavy type double hook finger(Options) | Heavy type double hook finge | |

| Option:Special jig for fixture | |||

| Conveying Angle | 4~7° | ||

| Solder Pot Type | Mechanical | ||

| Solder Pot Material | Casting Iron | ||

| Wave Height Adjustment | Inverter: Digital Control by PC | ||

| Cooling type | Air Cooling Option: Water cooling | ||

| Solder Pot Heating Power | 13.5KW | 18KW | |

| Max Solder Pot Temperature | 300℃ | ||

| Solder Pot Capacity | Approx.480kg | Approx.550kg | Approx.640kg |

| Wave Driving Power | 180W*2 3PH 220 VAC | ||

| Solder Pot Warm-up Time | Approx.150min(setting: 250℃) | ||

| Temperature Control Mode | PID | ||

| Finger Cleaning System | Brush | ||

Note:4 sections of preheating can be customized,and the length is 2.3m

Website:https://www.pcbcuttingmachine.com

Contacts:Eva Liu +8613450659407 +8613416743702

Tel:+86-512-62751429

Skype:evaliuhuan

Email:caojun@hk-yush.com sales@yushunli.com evaliu@hk-yush.com

Address: Building H, GuoRui Pioneering Park,

No. 1068 Jinyang East Road, Lujia Town, Kunshan,Suzhou.

Postcode:215331

Dongguan Factory Address: 5th Floor, No.10,

Shanquan Road, Yongtou Village, Chang’an Town,

Dongguan City, Guangdong province, China.

Postcode:523843