Technical requirements:

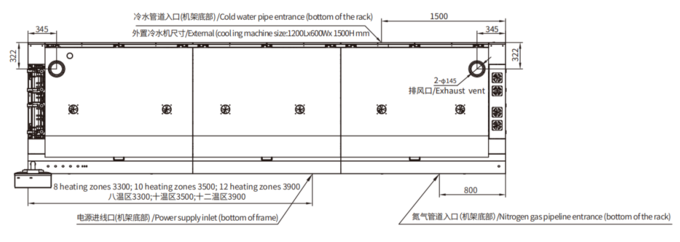

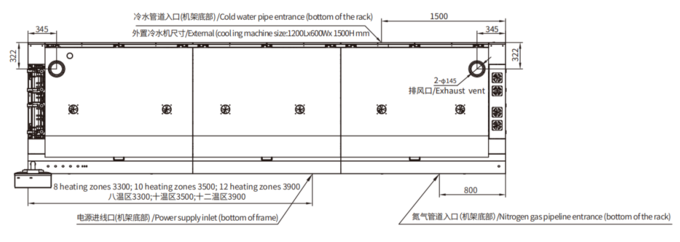

1.The customer to install control valve to control the import and export of the exhaust volume up to 145;

2.Each up to 145 entrance hole exhaust volume control in 15-20M³/min;

3.The main power supply: 3 380V diameter AC five wire, the main power line diameter of more than 35mm²;

4.Nitrogen and cold water pipe line entrance: 1/2 "hose."

Product Features

1.High heat energy:professional heat energy supply theoretical basis,through matching the appropriate heating power and volume to ensure large heat energy supply.Sufficient thermal energy to generate optimal thermal efficiency,maximize the productivity in short heating zones.

2.Low energy consumption:theoretical design and practical testing,through customer verification,obtain the best repeatability results CPK value,get the lowest energy consumption in the factory site.

3.Thermal equalization:theoretical and practical verification,ensure to achieve the minimum heat absorption difference between small and large components with the same speed,the same temperature setting,achieve the best equilibrium.

4.Large size:can handle larger size PCB in the same size machine;double tracks machine can produce PCB with 300mm in width at the same time,and PCB with 550mm in width with single track setting,which can meet the demand of many customers.

| SE series reflow oven main specifications | ||||||||||

| Model No | YSL-708AHSE | YSL-708HSE | YSL-708NHSE | YSL-710AHSE | YSL-710HSE | YSL-710NHSE | YSL-712AHSE | YSL-712HSE | YSL-712NHSE | YSL-706AHSE |

| Heating System | ||||||||||

| Heating Zone | 8 heating zones, 16 heating modules | 10 heating zones, 20 heating modules | 12 heating zones, 24 heating modules | 6 heating zones, 12 heating modules | ||||||

| Heating Length | 2950mm | 3670mm | 4350mm | 2230mm | ||||||

| Cooling Type | Double cooling:enforced air cooling/water cooling(Optional:three cooling zones) | Double cooling:forced air cooling | ||||||||

| Outlet Exhaust Diameter valume | 2-145,Exhaust demand 15m³/min*2 | |||||||||

| Conveyor System | ||||||||||

| Product width | Min50mm-Max400mm | |||||||||

| Conveying Direction | L→R,R→L | |||||||||

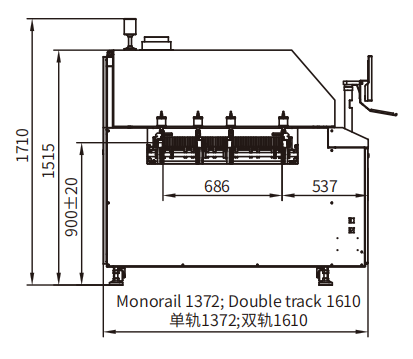

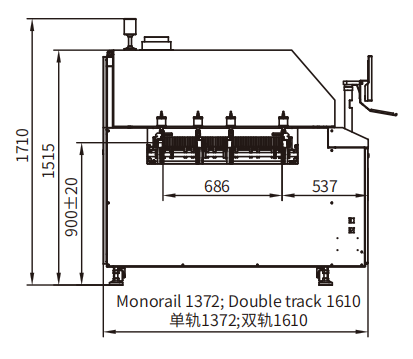

| Inlet Height | 900±20mm | |||||||||

| Fixed Rail Side | Front rail Fixed (Option:Rear Rail Fixed) | |||||||||

| Conveyor Type | Chain+mesh belt synchronous transmission | |||||||||

| Cmponent Height | Clearance based on the rail:above 30mm,below 20mm | |||||||||

| Conveying speed | 300mm-1500mm/min | |||||||||

| Control System | ||||||||||

| Power Supply | AC3 5W 380V 50/60Hz | |||||||||

| Total Power | 57KW | 71KW | 89KW | 45KW | ||||||

| Start Up Power | 30KW | 35KW | 40KW | 30KW | ||||||

| Running Power | 7.5KW | 9.5KW | 11.5KW | 6KW | ||||||

| Temperature Range | Room temperature to 320℃ | |||||||||

| Control type | PC+PLC Control system | |||||||||

| Rail Width Adjusting Mode | Electric+Manual | |||||||||

| Temp Control accuracy | ±1℃ | |||||||||

| PCB Temp Deviation | ±1℃ | |||||||||

| Data Storage | Process Data and status stotage | |||||||||

| Power Outage Protection | Equipped UPS | |||||||||

| Operation interface | Windows Chinese simplified,English online free switching | |||||||||

| General | ||||||||||

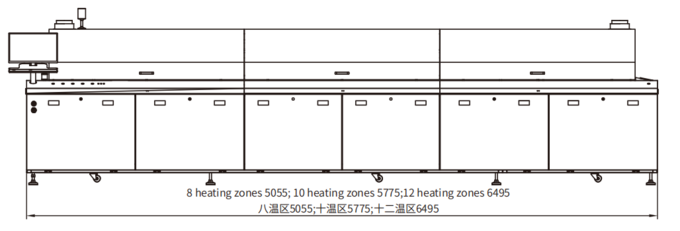

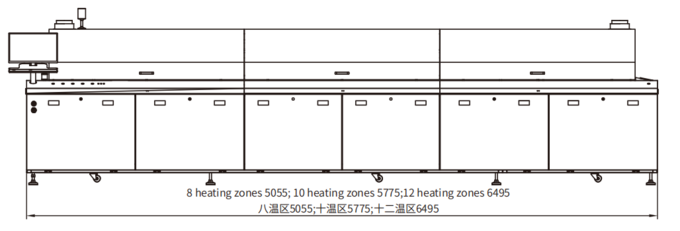

| Dimension(L*W*H) | 5055*1372*1515mm | 5775*1372*1515mm | 6495*1372*1515mm | 4335*1372*1515mm | ||||||

| Weight | 2000-2200KG | 2400-2600KG | 2800-3000KG | 1600-1800KG | ||||||

| Color | Bright wrinkled white | |||||||||

Technical requirements:

1.The customer to install control valve to control the import and export of the exhaust volume up to 145;

2.Each up to 145 entrance hole exhaust volume control in 15-20M³/min;

3.The main power supply: 3 380V diameter AC five wire, the main power line diameter of more than 35mm²;

4.Nitrogen and cold water pipe line entrance: 1/2 "hose."

Product Features

1.High heat energy:professional heat energy supply theoretical basis,through matching the appropriate heating power and volume to ensure large heat energy supply.Sufficient thermal energy to generate optimal thermal efficiency,maximize the productivity in short heating zones.

2.Low energy consumption:theoretical design and practical testing,through customer verification,obtain the best repeatability results CPK value,get the lowest energy consumption in the factory site.

3.Thermal equalization:theoretical and practical verification,ensure to achieve the minimum heat absorption difference between small and large components with the same speed,the same temperature setting,achieve the best equilibrium.

4.Large size:can handle larger size PCB in the same size machine;double tracks machine can produce PCB with 300mm in width at the same time,and PCB with 550mm in width with single track setting,which can meet the demand of many customers.

| SE series reflow oven main specifications | ||||||||||

| Model No | YSL-708AHSE | YSL-708HSE | YSL-708NHSE | YSL-710AHSE | YSL-710HSE | YSL-710NHSE | YSL-712AHSE | YSL-712HSE | YSL-712NHSE | YSL-706AHSE |

| Heating System | ||||||||||

| Heating Zone | 8 heating zones, 16 heating modules | 10 heating zones, 20 heating modules | 12 heating zones, 24 heating modules | 6 heating zones, 12 heating modules | ||||||

| Heating Length | 2950mm | 3670mm | 4350mm | 2230mm | ||||||

| Cooling Type | Double cooling:enforced air cooling/water cooling(Optional:three cooling zones) | Double cooling:forced air cooling | ||||||||

| Outlet Exhaust Diameter valume | 2-145,Exhaust demand 15m³/min*2 | |||||||||

| Conveyor System | ||||||||||

| Product width | Min50mm-Max400mm | |||||||||

| Conveying Direction | L→R,R→L | |||||||||

| Inlet Height | 900±20mm | |||||||||

| Fixed Rail Side | Front rail Fixed (Option:Rear Rail Fixed) | |||||||||

| Conveyor Type | Chain+mesh belt synchronous transmission | |||||||||

| Cmponent Height | Clearance based on the rail:above 30mm,below 20mm | |||||||||

| Conveying speed | 300mm-1500mm/min | |||||||||

| Control System | ||||||||||

| Power Supply | AC3 5W 380V 50/60Hz | |||||||||

| Total Power | 57KW | 71KW | 89KW | 45KW | ||||||

| Start Up Power | 30KW | 35KW | 40KW | 30KW | ||||||

| Running Power | 7.5KW | 9.5KW | 11.5KW | 6KW | ||||||

| Temperature Range | Room temperature to 320℃ | |||||||||

| Control type | PC+PLC Control system | |||||||||

| Rail Width Adjusting Mode | Electric+Manual | |||||||||

| Temp Control accuracy | ±1℃ | |||||||||

| PCB Temp Deviation | ±1℃ | |||||||||

| Data Storage | Process Data and status stotage | |||||||||

| Power Outage Protection | Equipped UPS | |||||||||

| Operation interface | Windows Chinese simplified,English online free switching | |||||||||

| General | ||||||||||

| Dimension(L*W*H) | 5055*1372*1515mm | 5775*1372*1515mm | 6495*1372*1515mm | 4335*1372*1515mm | ||||||

| Weight | 2000-2200KG | 2400-2600KG | 2800-3000KG | 1600-1800KG | ||||||

| Color | Bright wrinkled white | |||||||||

Website:https://www.pcbcuttingmachine.com

Contacts:Eva Liu +8613450659407 +8613416743702

Tel:+86-512-62751429

Skype:evaliuhuan

Email:caojun@hk-yush.com sales@yushunli.com evaliu@hk-yush.com

Address: Building H, GuoRui Pioneering Park,

No. 1068 Jinyang East Road, Lujia Town, Kunshan,Suzhou.

Postcode:215331

Dongguan Factory Address: 5th Floor, No.10,

Shanquan Road, Yongtou Village, Chang’an Town,

Dongguan City, Guangdong province, China.

Postcode:523843