Basic parameter Specifications:

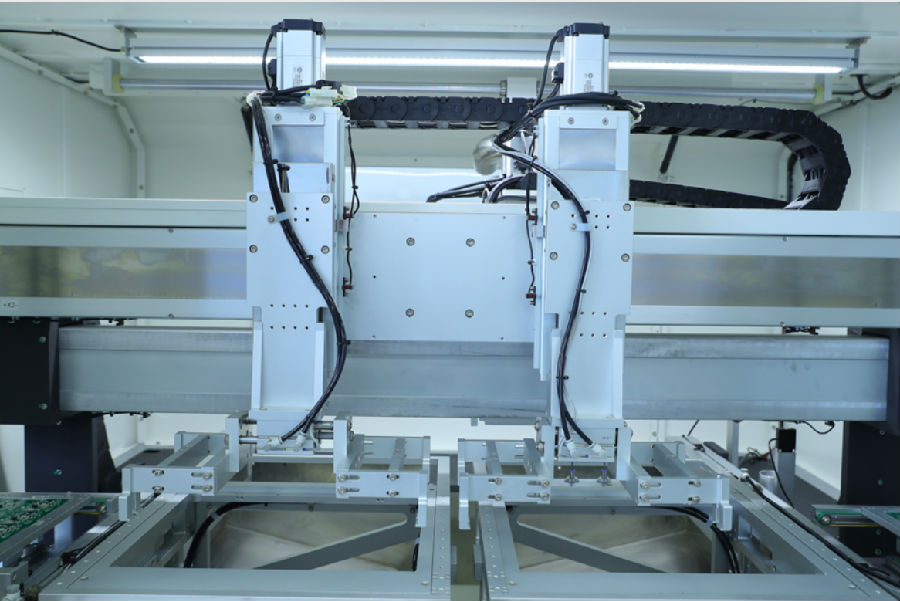

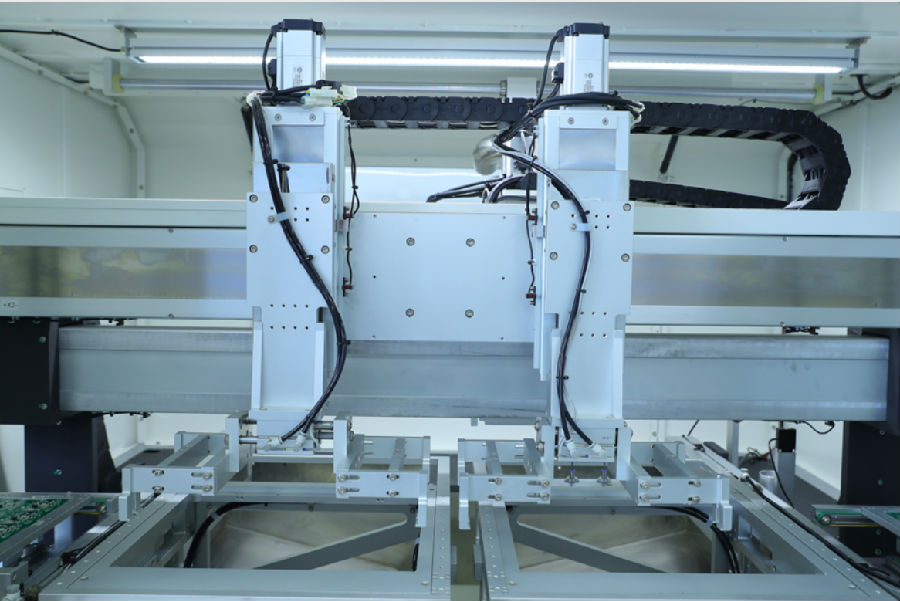

2. XYZ drive mode: ac servo motor

4. Program teaching mode: color ccd image intuitive teaching input

6. Upper vacuum power: 2hp, lower dust collector power: 3hp (option 5hp)

8. X-Y ac servo speed: 0-1000mm/sec;

Z ac servo speed: 0-800mm/sec

11. Cutting accuracy: ±0.02mm

13. Plate stress value: 300uε below

15. Pcb board cutting thickness: 0.2mm-6.0mm

17. Power consumption: 3.5kva

19. Vision system: high resolution digital camera

21. Mechanical fetching and releasing arm: anti-static vacuum suction nozzle

23. Discharging mode: belt conveying or vehicle output or rail conveying

25. Flow direction: left → right

27. Control mode: special controller

29. Machine size: 2014mm×1230mm×1650mm(d×w×h)

Two. Introduction to device configuration

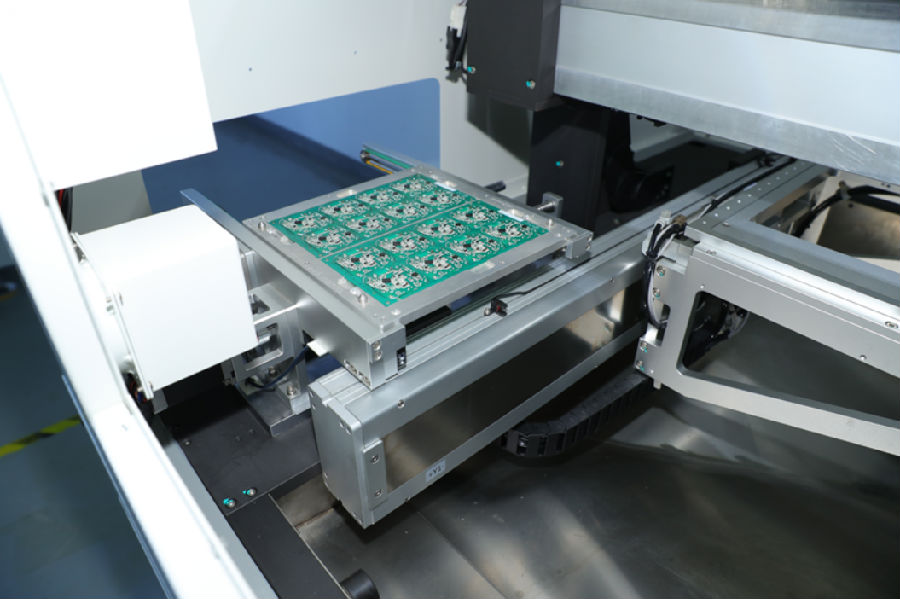

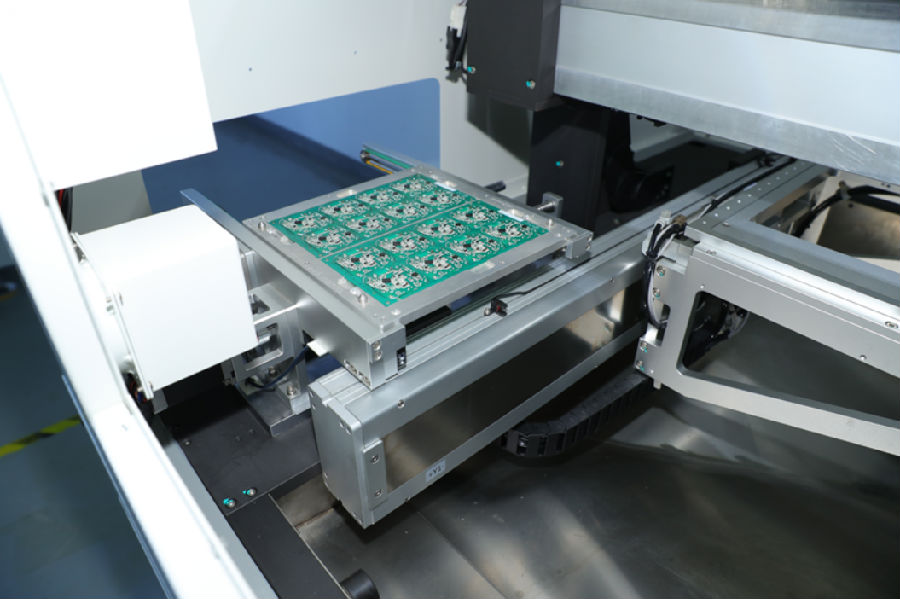

The product is clamped to the plate and placed on the processing platform. After the processing is completed, the clamping and placing track of the plate fixture is taken again and flows into the next process.

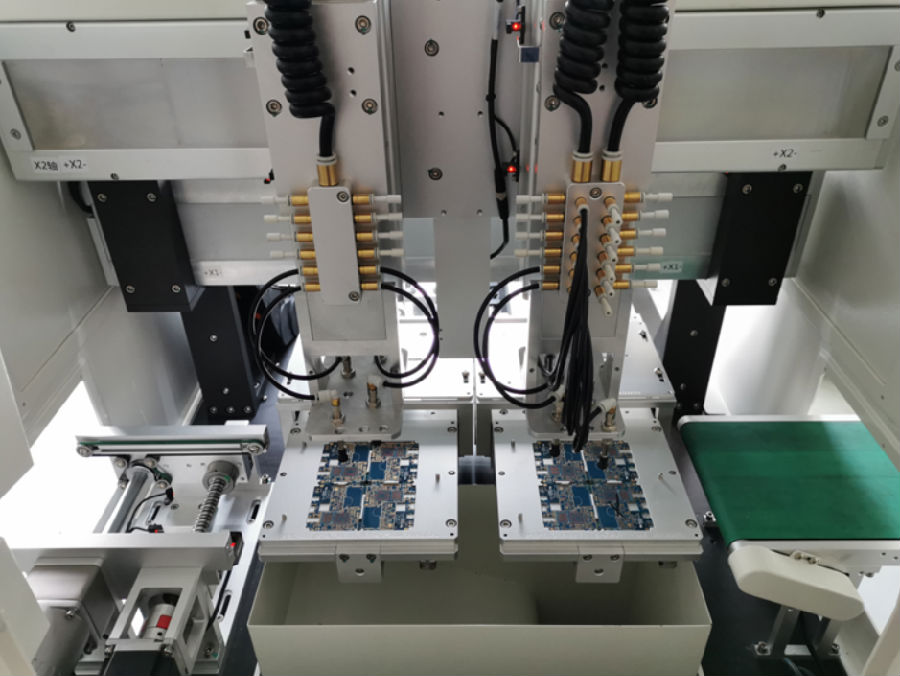

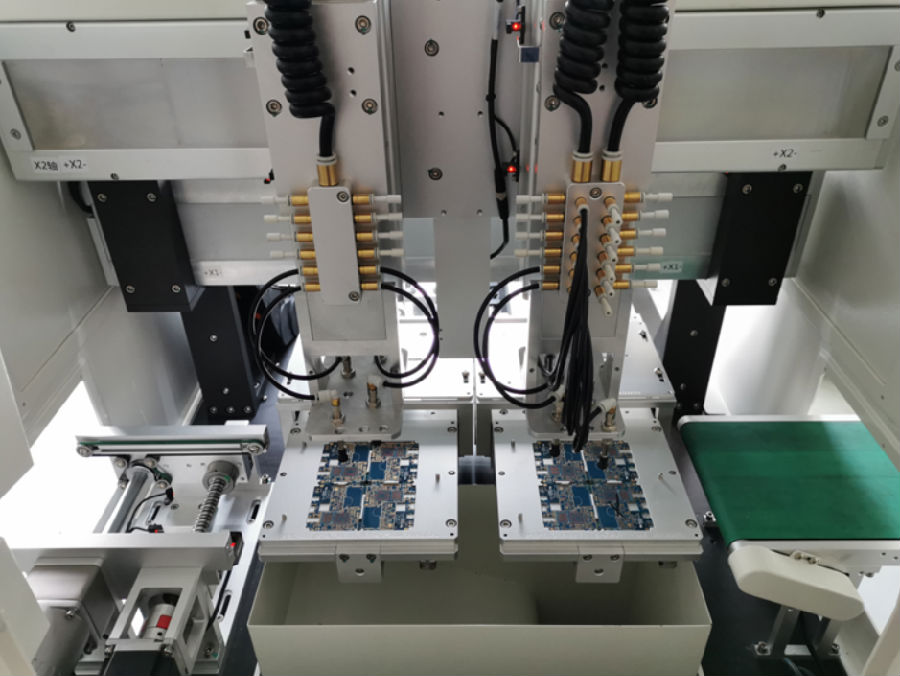

After the product cutting is completed by the online automatic plate splitter, the material clamping claw will take the entire product jig and place the discharging track to transport the next production process.

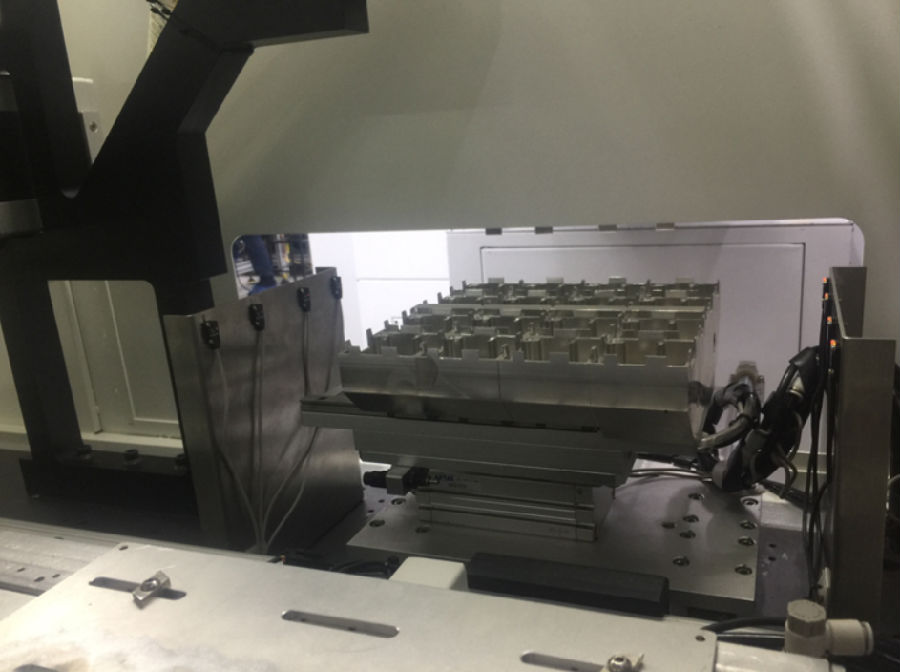

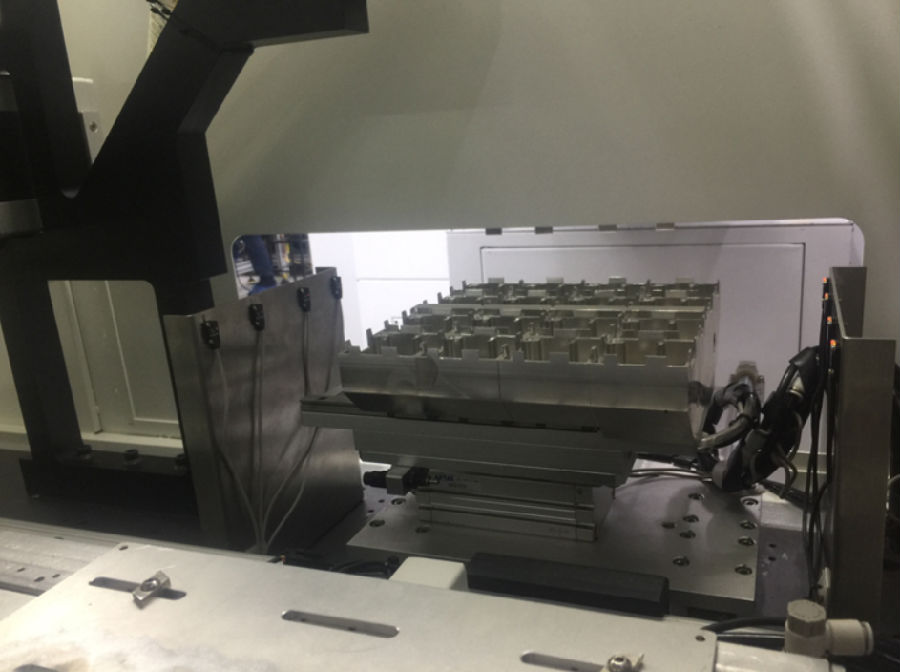

4.Automatic tool change mode

b. Built-in five groups of milling cutter library, easy to automatically replace the milling cutter, to meet the needs of plate processing.

a. Take and release device: automatic loading and unloading (modular vacuum suction claw, vacuum device, can be independently controlled)

c. Board speed: 0-1000mm/sec (adjustable)

Vacuum sucker feeding shaft to cut the product one-time vacuum suction, place the special product fixture to transport the next production process.

Basic parameter Specifications:

2. XYZ drive mode: ac servo motor

4. Program teaching mode: color ccd image intuitive teaching input

6. Upper vacuum power: 2hp, lower dust collector power: 3hp (option 5hp)

8. X-Y ac servo speed: 0-1000mm/sec;

Z ac servo speed: 0-800mm/sec

11. Cutting accuracy: ±0.02mm

13. Plate stress value: 300uε below

15. Pcb board cutting thickness: 0.2mm-6.0mm

17. Power consumption: 3.5kva

19. Vision system: high resolution digital camera

21. Mechanical fetching and releasing arm: anti-static vacuum suction nozzle

23. Discharging mode: belt conveying or vehicle output or rail conveying

25. Flow direction: left → right

27. Control mode: special controller

29. Machine size: 2014mm×1230mm×1650mm(d×w×h)

Two. Introduction to device configuration

The product is clamped to the plate and placed on the processing platform. After the processing is completed, the clamping and placing track of the plate fixture is taken again and flows into the next process.

After the product cutting is completed by the online automatic plate splitter, the material clamping claw will take the entire product jig and place the discharging track to transport the next production process.

4.Automatic tool change mode

b. Built-in five groups of milling cutter library, easy to automatically replace the milling cutter, to meet the needs of plate processing.

a. Take and release device: automatic loading and unloading (modular vacuum suction claw, vacuum device, can be independently controlled)

c. Board speed: 0-1000mm/sec (adjustable)

Vacuum sucker feeding shaft to cut the product one-time vacuum suction, place the special product fixture to transport the next production process.

Website:https://www.pcbcuttingmachine.com

Contacts:Eva Liu +8613450659407 +8613416743702

Tel:+86-512-62751429

Skype:evaliuhuan

Email:caojun@hk-yush.com sales@yushunli.com evaliu@hk-yush.com

Address: Building H, GuoRui Pioneering Park,

No. 1068 Jinyang East Road, Lujia Town, Kunshan,Suzhou.

Postcode:215331

Dongguan Factory Address: 5th Floor, No.10,

Shanquan Road, Yongtou Village, Chang’an Town,

Dongguan City, Guangdong province, China.

Postcode:523843