High speed plate distributor YS-4500

With the continuous development of the electronic industry, the production requirements of the substrate, an important component of electronic products, are increasingly Lei higher, to high precision. High density. High performance. Small volume development. In order to meet the requirements of the market, the company's long-term market research on the advantages of various brands in the world, widely listen to the views of all aspects of the user, to make this high-speed dual-mode board machine YS-4500.

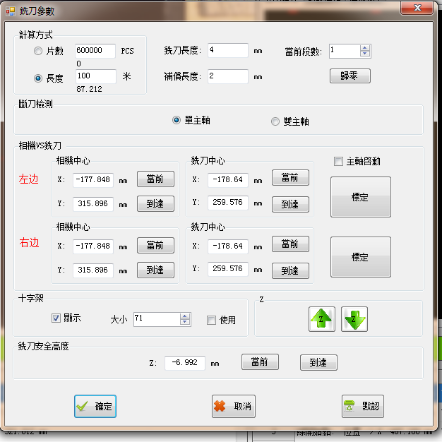

Software introduction

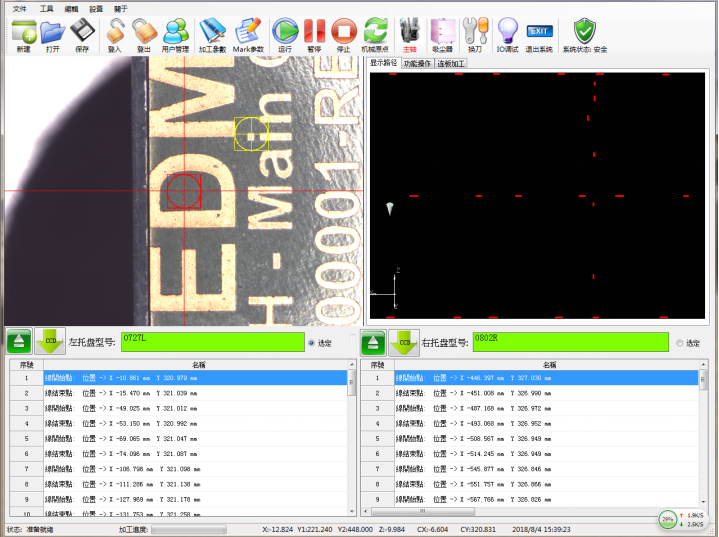

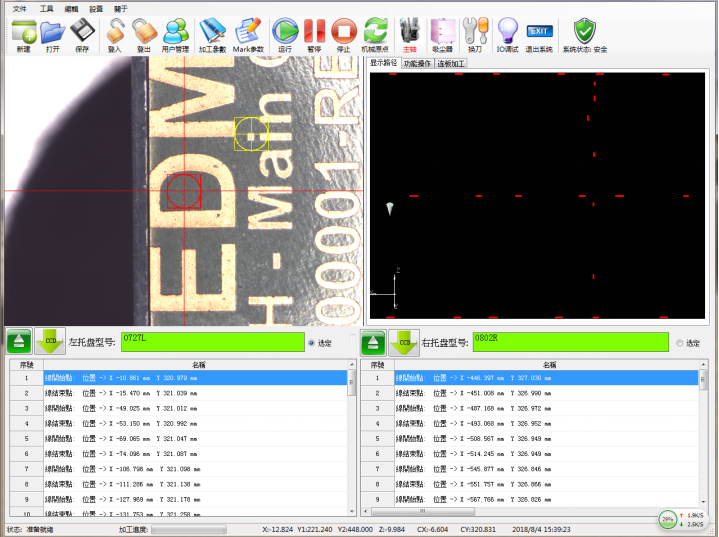

New generation identification system

1: Change the traditional circle, square and other geometric patterns can only be recognized. Can recognize any shape mark point

2: Not only with error correction function, but also accurate data, do not worry about the staff put the wrong board.

3: displacement function, can realize the fixture in the working table arbitrary placement

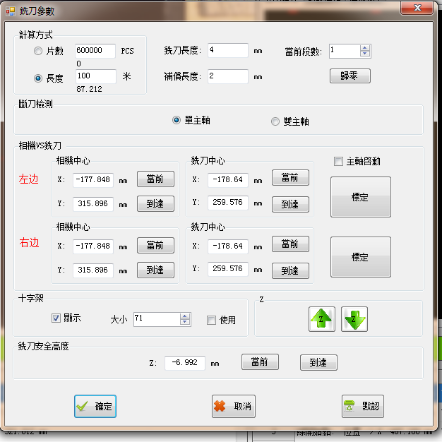

1: Change the traditional segmentation mode

2: Adjust the depth of the lower cutter according to the thickness of PCB, increase the utilization rate of the milling cutter and save the cost

3: Can be defined according to the needs of the product to determine the condition of the milling cutter

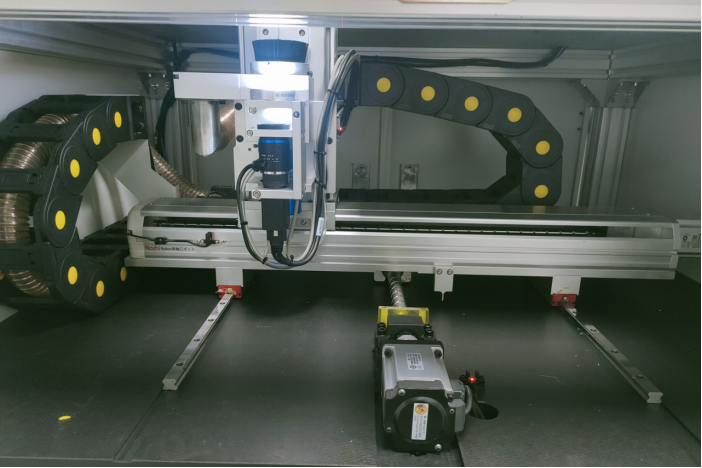

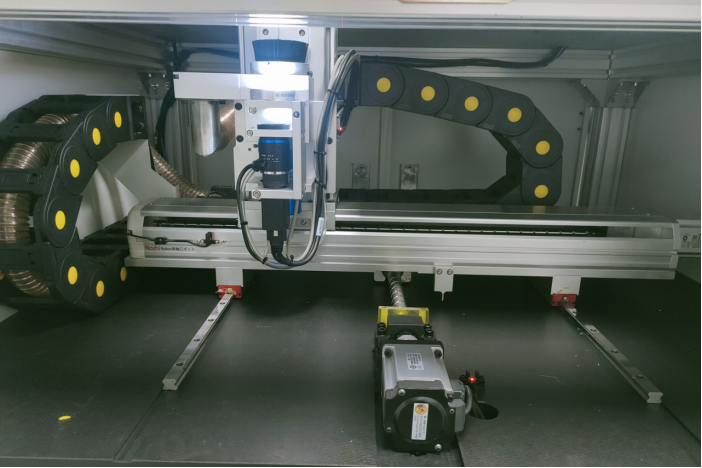

Introduction about the construction

Taiwan 60000 high-speed spindle is adopted.

Using WIN7 system operation interface, the configuration of high pixel color CCD amplification 10 times lens, auxiliary program teaching and editing simulation function, precision is more accurate, the image is clearer.

Electric control layout

Electronic control - on-line

1: clear, easy maintenance

2: bus mode, simple connection

3: modular design, not high requirements for maintenance personnel

Parameters and main accessories of

X/Y cutting speed: 0~100mm/s

Machine repetition accuracy: ±0.02

Maximum size of the board: 400mm*500mm

X,Y,Z control mode: industrial motion controller + industrial computer

X,Y,Z drive mode: Panasonic servo electric power

Man-machine operation and data storage: industrial computers

Cutting accuracy: ±0.1

Spindle speed: Taiwan spindle Max 60000rpm

Cutting form: straight line, circle, arc, U shape, L shape, etc

Image: Smart Industrial CCD

Operation interface: Chinese/English double interface

Fidicuial Mark: CCD automatic alignment function

Program preview: CCD path simulation function

Host voltage: AC 220V 50/60Hz

Air pressure: 5.5KG/CM²

Host size: 1150 x 1050 x 1580 (L X H X D)mm

Main engine weight: 450kg

Dust collection mode: next dust collection

Dust collector: 2HP

Dust collector power supply: AC 380V 50/60Hz

Size of dust collector: 650 x 400 x 1250 (L X H X D)mm

Dust collector weight: 103kg

The main parts of the plate machine

Lead screw: Taiwan TBI C5 grinding lead screw

Guide rail: Taiwan PMI linear guide rail

Spindle: Taiwan spindle Max 60000rpm

Servo motor: Panasonic A6 servo motor

Industrial control host: industrial computer

Monitor: LCD19"

CCD: GIGE industrial intelligent CCD

Lens: Industrial HD lens

Light source: Industrial dimmer +50mmLED ring light source

Power Supply: Taiwan Mingwei

Relay: Omron relay

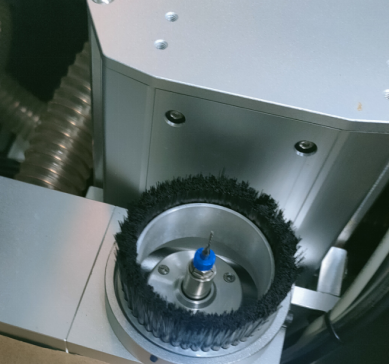

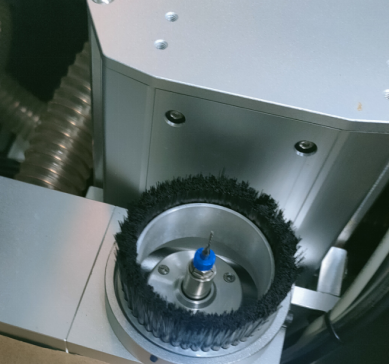

Introduction to dust collecting machine

Clean vacuum mechanism

1: Patented design of brush design, excellent vacuum suburb fruit

2: module suction structure, to ensure long-term dust

YS-UA02 high efficiency vacuum cleaner is specially equipped with the lower vacuum separator, super dust removal capacity, the lower vacuum mode with the unique design of the separator can effectively deal with the dust produced in the process of dividing the board, can well protect the cleaning of products and workshop environment and staff health.

| Motor specification | 2HP 380V 50Hz 3-phase |

| Output power | 1.5KW |

| Suction air volume | 3 m³/min |

| Static pressure | -2000mm-AQ |

| Inlet diameter | 50mm |

| Outlet diameter | 100mm |

| Noise | <65dB |

| Net weight | 103Kg |

| Dimension | 650*400*1250mm |

Plate splitting machine features:

1: Simple operation, intelligent

2: Good stability

3: simple structure, easy maintenance

4: vacuum suburb fruit good

Summary

High speed plate distributor YS-4500

With the continuous development of the electronic industry, the production requirements of the substrate, an important component of electronic products, are increasingly Lei higher, to high precision. High density. High performance. Small volume development. In order to meet the requirements of the market, the company's long-term market research on the advantages of various brands in the world, widely listen to the views of all aspects of the user, to make this high-speed dual-mode board machine YS-4500.

Software introduction

New generation identification system

1: Change the traditional circle, square and other geometric patterns can only be recognized. Can recognize any shape mark point

2: Not only with error correction function, but also accurate data, do not worry about the staff put the wrong board.

3: displacement function, can realize the fixture in the working table arbitrary placement

1: Change the traditional segmentation mode

2: Adjust the depth of the lower cutter according to the thickness of PCB, increase the utilization rate of the milling cutter and save the cost

3: Can be defined according to the needs of the product to determine the condition of the milling cutter

Introduction about the construction

Taiwan 60000 high-speed spindle is adopted.

Using WIN7 system operation interface, the configuration of high pixel color CCD amplification 10 times lens, auxiliary program teaching and editing simulation function, precision is more accurate, the image is clearer.

Electric control layout

Electronic control - on-line

1: clear, easy maintenance

2: bus mode, simple connection

3: modular design, not high requirements for maintenance personnel

Parameters and main accessories of

X/Y cutting speed: 0~100mm/s

Machine repetition accuracy: ±0.02

Maximum size of the board: 400mm*500mm

X,Y,Z control mode: industrial motion controller + industrial computer

X,Y,Z drive mode: Panasonic servo electric power

Man-machine operation and data storage: industrial computers

Cutting accuracy: ±0.1

Spindle speed: Taiwan spindle Max 60000rpm

Cutting form: straight line, circle, arc, U shape, L shape, etc

Image: Smart Industrial CCD

Operation interface: Chinese/English double interface

Fidicuial Mark: CCD automatic alignment function

Program preview: CCD path simulation function

Host voltage: AC 220V 50/60Hz

Air pressure: 5.5KG/CM²

Host size: 1150 x 1050 x 1580 (L X H X D)mm

Main engine weight: 450kg

Dust collection mode: next dust collection

Dust collector: 2HP

Dust collector power supply: AC 380V 50/60Hz

Size of dust collector: 650 x 400 x 1250 (L X H X D)mm

Dust collector weight: 103kg

The main parts of the plate machine

Lead screw: Taiwan TBI C5 grinding lead screw

Guide rail: Taiwan PMI linear guide rail

Spindle: Taiwan spindle Max 60000rpm

Servo motor: Panasonic A6 servo motor

Industrial control host: industrial computer

Monitor: LCD19"

CCD: GIGE industrial intelligent CCD

Lens: Industrial HD lens

Light source: Industrial dimmer +50mmLED ring light source

Power Supply: Taiwan Mingwei

Relay: Omron relay

Introduction to dust collecting machine

Clean vacuum mechanism

1: Patented design of brush design, excellent vacuum suburb fruit

2: module suction structure, to ensure long-term dust

YS-UA02 high efficiency vacuum cleaner is specially equipped with the lower vacuum separator, super dust removal capacity, the lower vacuum mode with the unique design of the separator can effectively deal with the dust produced in the process of dividing the board, can well protect the cleaning of products and workshop environment and staff health.

| Motor specification | 2HP 380V 50Hz 3-phase |

| Output power | 1.5KW |

| Suction air volume | 3 m³/min |

| Static pressure | -2000mm-AQ |

| Inlet diameter | 50mm |

| Outlet diameter | 100mm |

| Noise | <65dB |

| Net weight | 103Kg |

| Dimension | 650*400*1250mm |

Plate splitting machine features:

1: Simple operation, intelligent

2: Good stability

3: simple structure, easy maintenance

4: vacuum suburb fruit good

Summary

Website:https://www.pcbcuttingmachine.com

Contacts:Eva Liu +8613450659407 +8613416743702

Tel:+86-512-62751429

Skype:evaliuhuan

Email:caojun@hk-yush.com sales@yushunli.com evaliu@hk-yush.com

Address: Building H, GuoRui Pioneering Park,

No. 1068 Jinyang East Road, Lujia Town, Kunshan,Suzhou.

Postcode:215331

Dongguan Factory Address: 5th Floor, No.10,

Shanquan Road, Yongtou Village, Chang’an Town,

Dongguan City, Guangdong province, China.

Postcode:523843