The role and characteristics of PCB boring machine

The PCB splicing machine is a machine for dividing the stamp hole connection and the irregular PCB board. Also called PCB curve board machine, desktop curve board machine, stamp hole PCB board machine. The PCB boring machine is an important process in the PCB manufacturing process. The PCB slab refers to the cutting of the customer's required graphics by the boring tool according to the engineering design. When the milling cutter wears to a certain extent, the broken knives will occur. The leaky situation occurs. If the defective production board is not shipped to the customer according to the customer's requirements, the PCBA (Printed Circuit Board + Assembly, which means that the PCB blank board passes through the SMT upper part and then passes through the DIP plug-in process) cannot be used.

Successful installation on the product, resulting in PCBA scrap.

The jaws are divided into rough and fine, and the conventional jaw depth of the cutter is 16.5 mm, and the thickness of the stack is smaller than the blade length of the cutter.

If the thickness of the PCB is equal to or greater than the length of the tool, the rotation of the fixed structure above the tool during the roughing process will burn out the PCB. In order to avoid damage to the PCB caused by the fixed structure above the tool, the fixed structure and the PCB are required. A gap is formed between them, so the seesaw depth of 16.5 mm can only perform the boring operation on the 4pnl PCB board, and the processing efficiency is low.

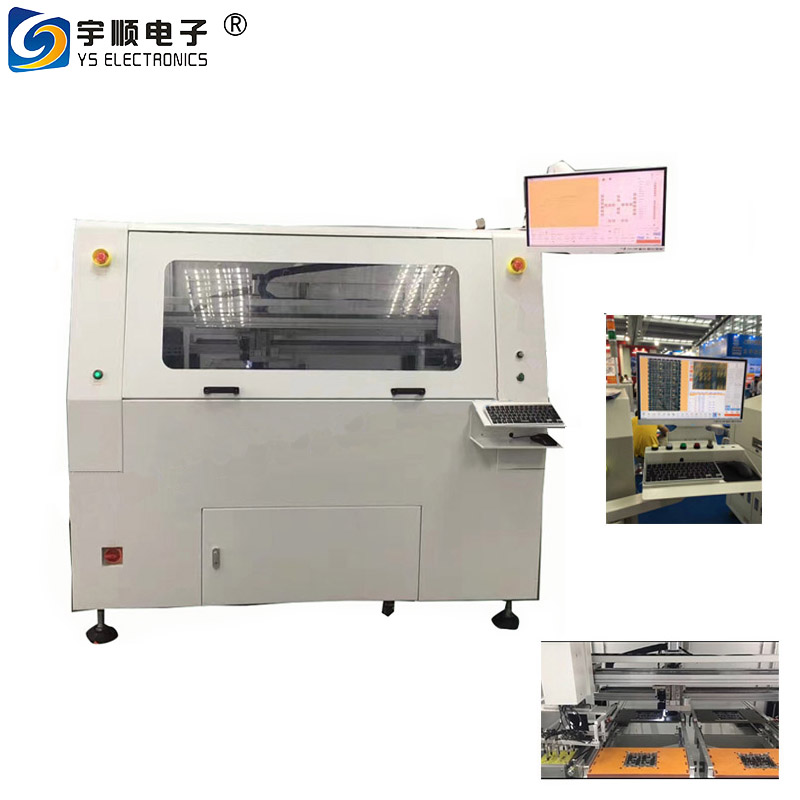

PCB board machine features:

1. Desktop single table cutting machine with speed up to 100mm/s and positioning speed of 500mm/s.

2. Uninterrupted continuous cutting during loading and unloading.

3. High-quality spindle system enables the system to accelerate and decelerate quickly, reducing synchronization time and increasing productivity while maintaining high precision.

4. Use high quality hardware to ensure high steel and high performance.

5. All lead screws are covered to prevent dust and dirt from entering, thus improving the life and performance of the shaft.

Features:

1. Online automatic PCB separator can be automatically loaded, cut and unloaded to meet the needs of automatic factories.5. Double table movement can simultaneously cut and place PCB to improve operation efficiency.

The role and characteristics of PCB boring machine

The PCB splicing machine is a machine for dividing the stamp hole connection and the irregular PCB board. Also called PCB curve board machine, desktop curve board machine, stamp hole PCB board machine. The PCB boring machine is an important process in the PCB manufacturing process. The PCB slab refers to the cutting of the customer's required graphics by the boring tool according to the engineering design. When the milling cutter wears to a certain extent, the broken knives will occur. The leaky situation occurs. If the defective production board is not shipped to the customer according to the customer's requirements, the PCBA (Printed Circuit Board + Assembly, which means that the PCB blank board passes through the SMT upper part and then passes through the DIP plug-in process) cannot be used.

Successful installation on the product, resulting in PCBA scrap.

The jaws are divided into rough and fine, and the conventional jaw depth of the cutter is 16.5 mm, and the thickness of the stack is smaller than the blade length of the cutter.

If the thickness of the PCB is equal to or greater than the length of the tool, the rotation of the fixed structure above the tool during the roughing process will burn out the PCB. In order to avoid damage to the PCB caused by the fixed structure above the tool, the fixed structure and the PCB are required. A gap is formed between them, so the seesaw depth of 16.5 mm can only perform the boring operation on the 4pnl PCB board, and the processing efficiency is low.

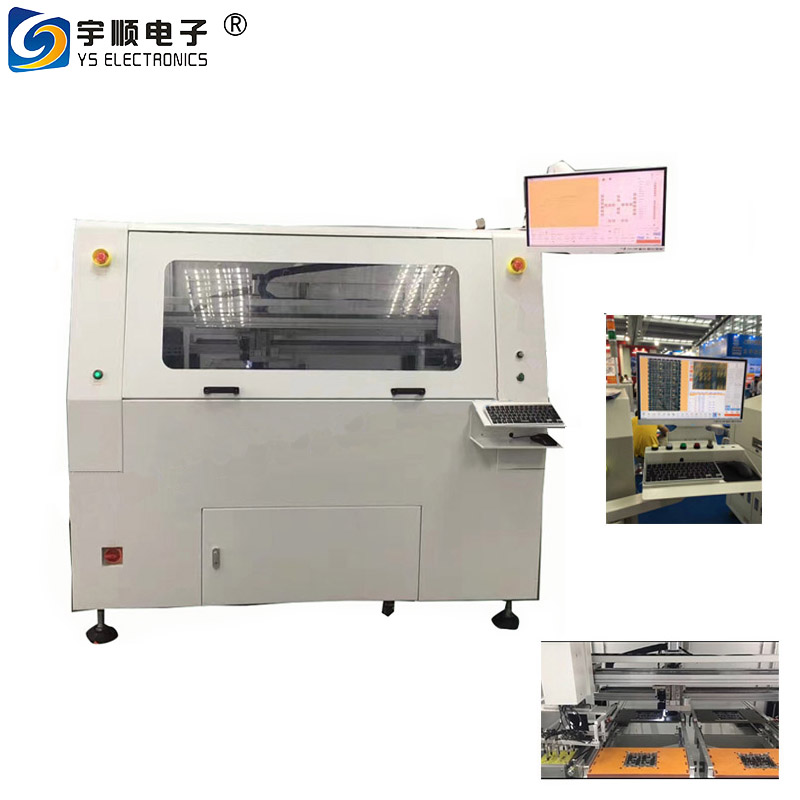

PCB board machine features:

1. Desktop single table cutting machine with speed up to 100mm/s and positioning speed of 500mm/s.

2. Uninterrupted continuous cutting during loading and unloading.

3. High-quality spindle system enables the system to accelerate and decelerate quickly, reducing synchronization time and increasing productivity while maintaining high precision.

4. Use high quality hardware to ensure high steel and high performance.

5. All lead screws are covered to prevent dust and dirt from entering, thus improving the life and performance of the shaft.

Features:

1. Online automatic PCB separator can be automatically loaded, cut and unloaded to meet the needs of automatic factories.5. Double table movement can simultaneously cut and place PCB to improve operation efficiency.

Website:https://www.pcbcuttingmachine.com

Contacts:Eva Liu +8613450659407 +8613416743702

Tel:+86-512-62751429

Skype:evaliuhuan

Email:caojun@hk-yush.com sales@yushunli.com evaliu@hk-yush.com

Address: Building H, GuoRui Pioneering Park,

No. 1068 Jinyang East Road, Lujia Town, Kunshan,Suzhou.

Postcode:215331

Dongguan Factory Address: 5th Floor, No.10,

Shanquan Road, Yongtou Village, Chang’an Town,

Dongguan City, Guangdong province, China.

Postcode:523843