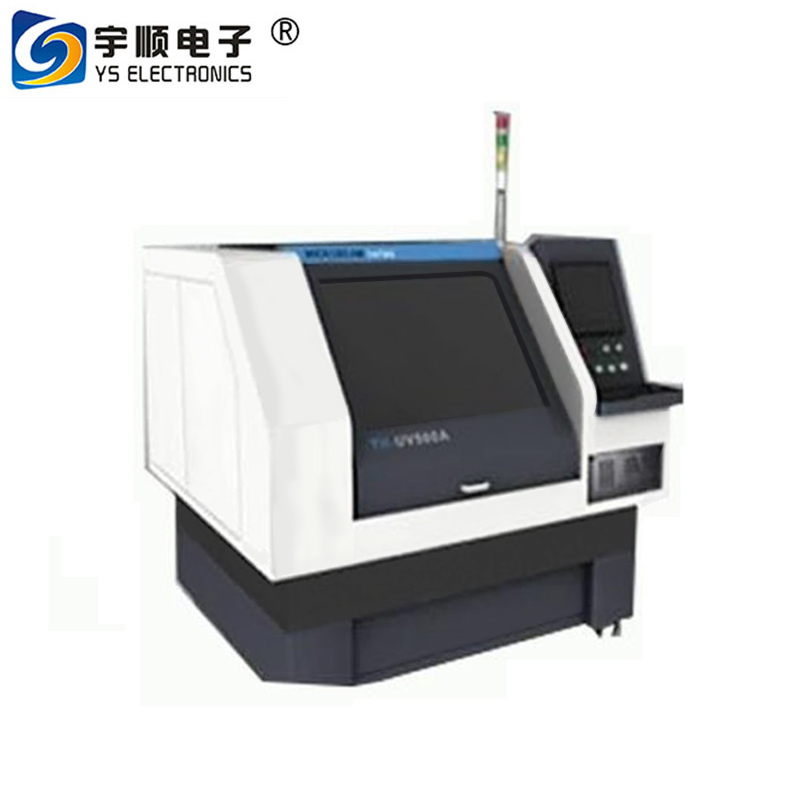

laser cutter

A laser cutting machine is a laser beam emitted from a laser that is focused by a light path system into a laser beam of high power density. The laser beam is irradiated onto the surface of the workpiece to bring the workpiece to a melting point or boiling point, while the high-pressure gas coaxial with the beam blows away the molten or vaporized metal.

As the beam moves relative to the workpiece, the material is finally slit, thereby achieving the purpose of cutting.

Laser cutting processing replaces traditional mechanical knives with invisible beams. It has high precision, fast cutting, is not limited to cutting pattern limitation, saves materials by automatic typesetting, smooth cuts, low processing cost, etc., and will gradually improve or replace Traditional metal cutting process equipment. The mechanical part of the laser cutter head has no contact with the workpiece, and it will not scratch the surface of the workpiece during operation; the laser cutting speed is fast, the slit is smooth and flat, and generally no subsequent processing is required; the cutting heat affected zone is small, the sheet deformation is small, and the slit is narrow ( 0.1mm~0.3mm); no mechanical stress in the incision, no shear burr; high processing precision, good repeatability, no damage to the surface of the material; NC programming, can process any plan, can cut the whole board with large format, no need Open the mold, saving time and economy.

1. Laser cutting machine YSV-4A, dual platform, greatly improving production efficiency, is specially designed for FPC and PCB processing.

2. High-performance laser: It adopts the international first-line brand solid-state UV laser, which has the advantages of good beam quality, small focusing spot, uniform power distribution, small thermal effect, small slit width and high cutting quality.

2. Efficient and fast FPC/PCB external cutting, drilling and film opening window, fingerprint identification chip cutting, TF memory card sub-board, mobile phone camera module cutting and other applications.

3. Fully automatic positioning: It adopts high-precision CCD to automatically locate and focus, so that the positioning is fast, accurate and high precision without manual intervention. 4. Simple operation, realize the same type of one-button mode, greatly improve production efficiency.

5. Blocking, layering, specifying blocks or selected areas are cut and directly formed, and the cutting edges are round and smooth, smooth and burr-free, and no overflowing glue.

6. The product can be arranged in multiple rows for automatic positioning and cutting, especially suitable for cutting of fine, difficult and complicated patterns.

7. Exhaust gas treatment system: The suction system can completely eliminate the cutting exhaust gas, avoiding the harm to the operator and the pollution to the environment.

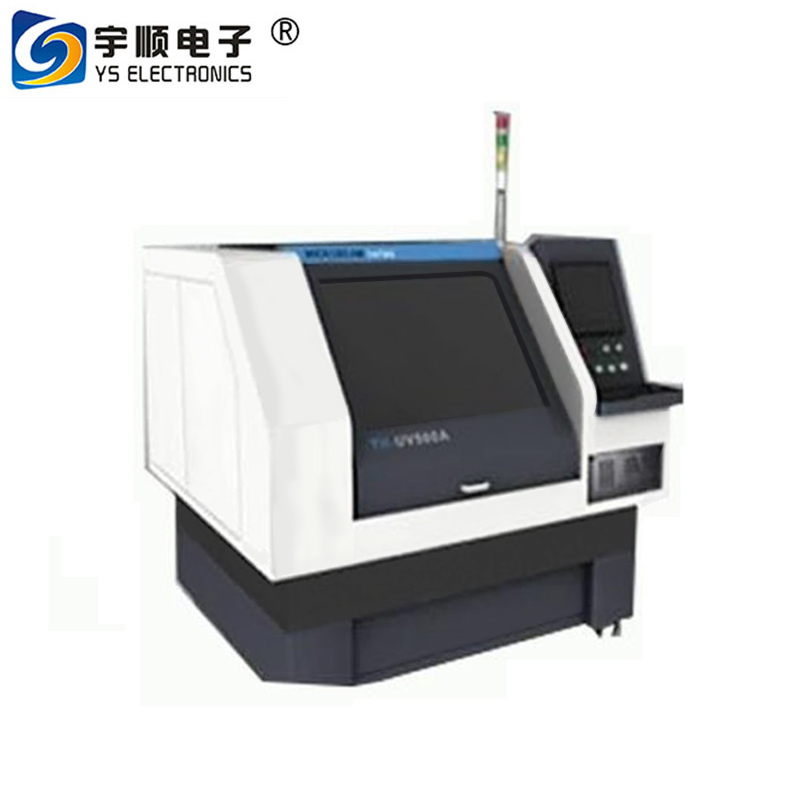

laser cutter

A laser cutting machine is a laser beam emitted from a laser that is focused by a light path system into a laser beam of high power density. The laser beam is irradiated onto the surface of the workpiece to bring the workpiece to a melting point or boiling point, while the high-pressure gas coaxial with the beam blows away the molten or vaporized metal.

As the beam moves relative to the workpiece, the material is finally slit, thereby achieving the purpose of cutting.

Laser cutting processing replaces traditional mechanical knives with invisible beams. It has high precision, fast cutting, is not limited to cutting pattern limitation, saves materials by automatic typesetting, smooth cuts, low processing cost, etc., and will gradually improve or replace Traditional metal cutting process equipment. The mechanical part of the laser cutter head has no contact with the workpiece, and it will not scratch the surface of the workpiece during operation; the laser cutting speed is fast, the slit is smooth and flat, and generally no subsequent processing is required; the cutting heat affected zone is small, the sheet deformation is small, and the slit is narrow ( 0.1mm~0.3mm); no mechanical stress in the incision, no shear burr; high processing precision, good repeatability, no damage to the surface of the material; NC programming, can process any plan, can cut the whole board with large format, no need Open the mold, saving time and economy.

1. Laser cutting machine YSV-4A, dual platform, greatly improving production efficiency, is specially designed for FPC and PCB processing.

2. High-performance laser: It adopts the international first-line brand solid-state UV laser, which has the advantages of good beam quality, small focusing spot, uniform power distribution, small thermal effect, small slit width and high cutting quality.

2. Efficient and fast FPC/PCB external cutting, drilling and film opening window, fingerprint identification chip cutting, TF memory card sub-board, mobile phone camera module cutting and other applications.

3. Fully automatic positioning: It adopts high-precision CCD to automatically locate and focus, so that the positioning is fast, accurate and high precision without manual intervention. 4. Simple operation, realize the same type of one-button mode, greatly improve production efficiency.

5. Blocking, layering, specifying blocks or selected areas are cut and directly formed, and the cutting edges are round and smooth, smooth and burr-free, and no overflowing glue.

6. The product can be arranged in multiple rows for automatic positioning and cutting, especially suitable for cutting of fine, difficult and complicated patterns.

7. Exhaust gas treatment system: The suction system can completely eliminate the cutting exhaust gas, avoiding the harm to the operator and the pollution to the environment.

Website:https://www.pcbcuttingmachine.com

Contacts:Eva Liu +8613450659407 +8613416743702

Tel:+86-512-62751429

Skype:evaliuhuan

Email:caojun@hk-yush.com sales@yushunli.com evaliu@hk-yush.com

Address: Building H, GuoRui Pioneering Park,

No. 1068 Jinyang East Road, Lujia Town, Kunshan,Suzhou.

Postcode:215331

Dongguan Factory Address: 5th Floor, No.10,

Shanquan Road, Yongtou Village, Chang’an Town,

Dongguan City, Guangdong province, China.

Postcode:523843