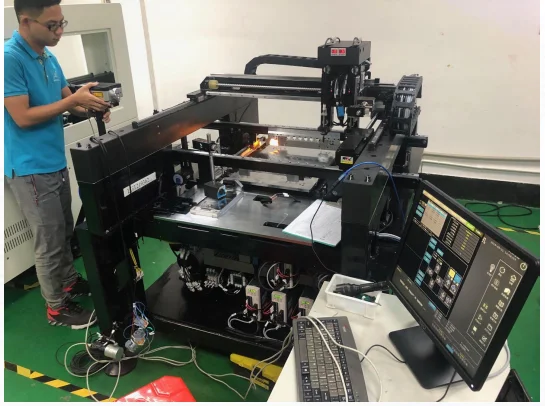

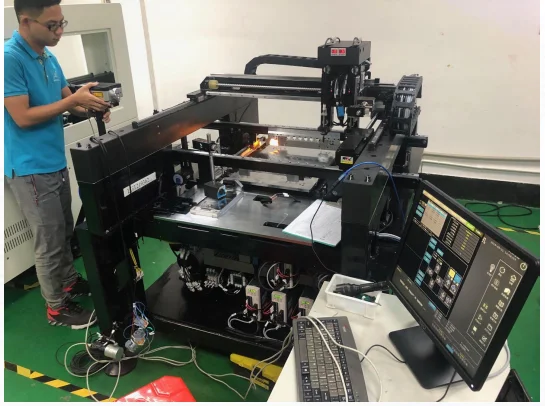

Production equipment - Excellent architecture)

1.Frame: High precision and stable structure integrated frame to ensure stability for high speed mounting work.

2.Electric cabinet: Safe and convenient drawer type design, compared with the built-in electronic control structure is easier to maintain and clean. Visual electronic control component design of the equipment is easy to manage by maintenance personnel, eliminate electronic control risks timely, improve the safety of the machine and prolong its service life.

3.The equipment uses silent vacuum pump with low noise and stable negative pressure source. The air source consumption of our equipment is as low as 1L/Min, which is far less than the other machines using vacuum generator (air source consumption is more than 100L/Min), and save the air source consumption for customers on the production site. If the gas source consumption is too large, the load of the air compressor in the factory will be increased, and if it is serious, the pressure of the production line will be unstable and the production will be affected.

4.Beam: Natural marble material, after grinding processing, the straightness error of guide rail assembly of the equipment can be controlled within 5 microns, to ensure the high precision requirements, the long-term operation and not easy to deformation.

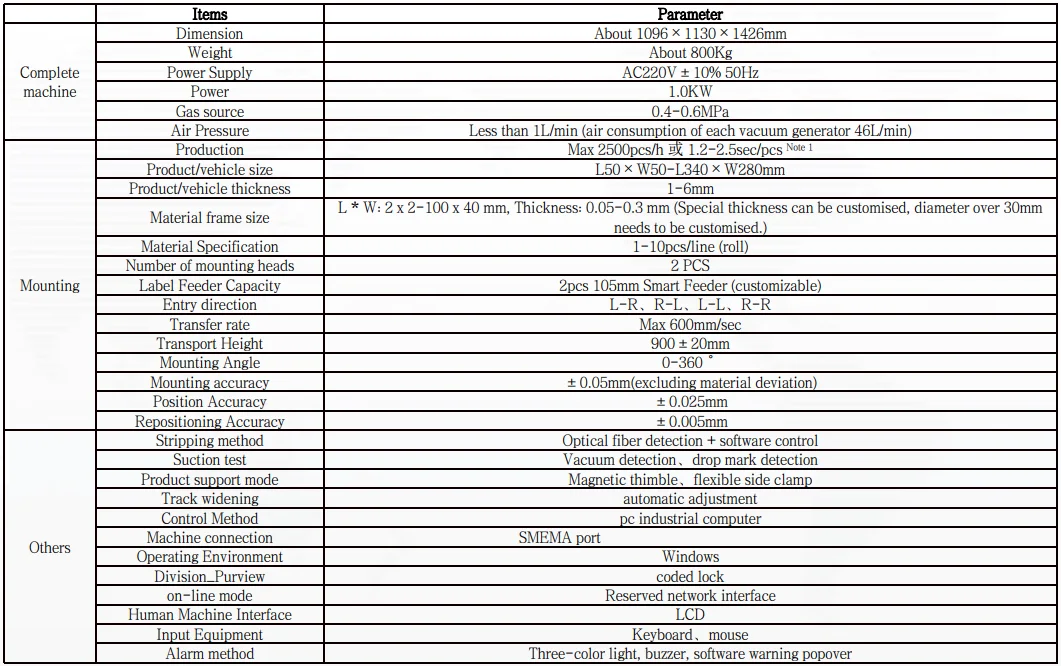

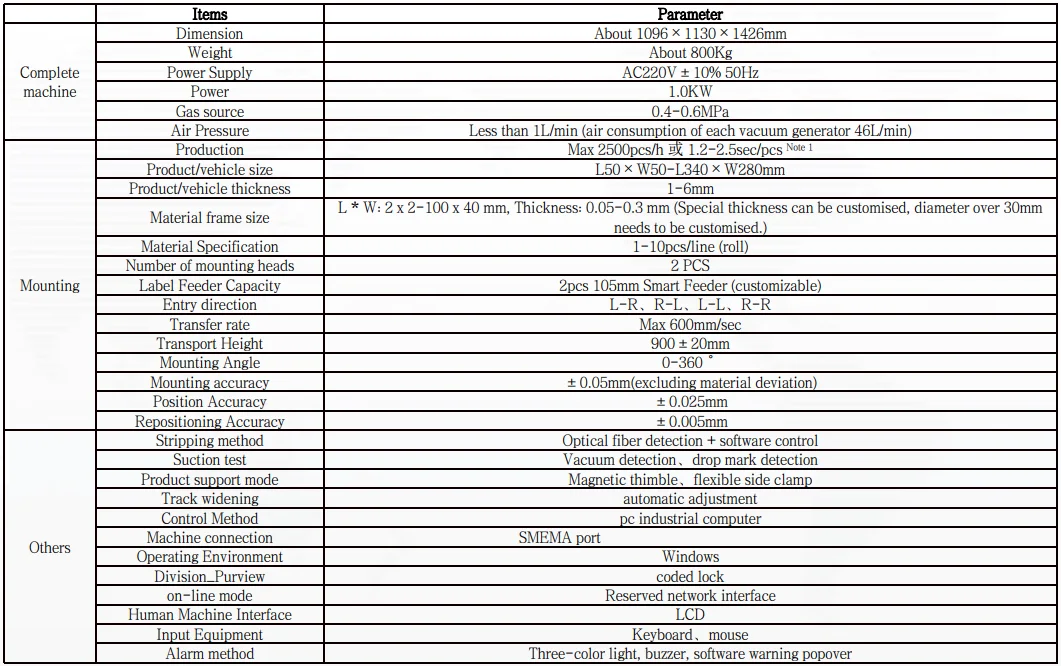

T2Parameter

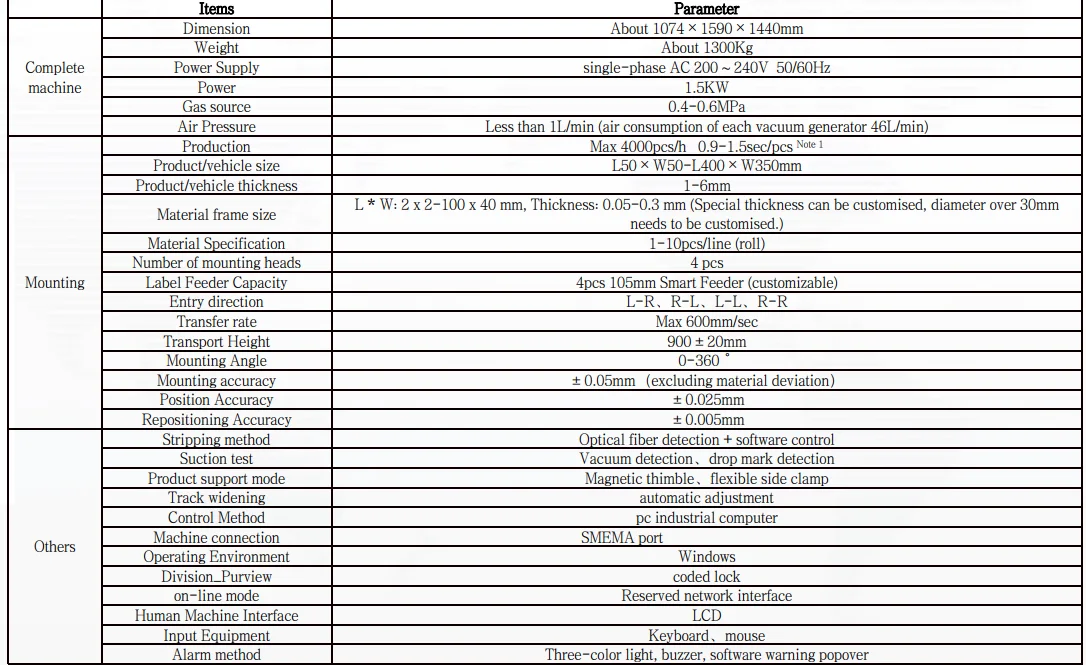

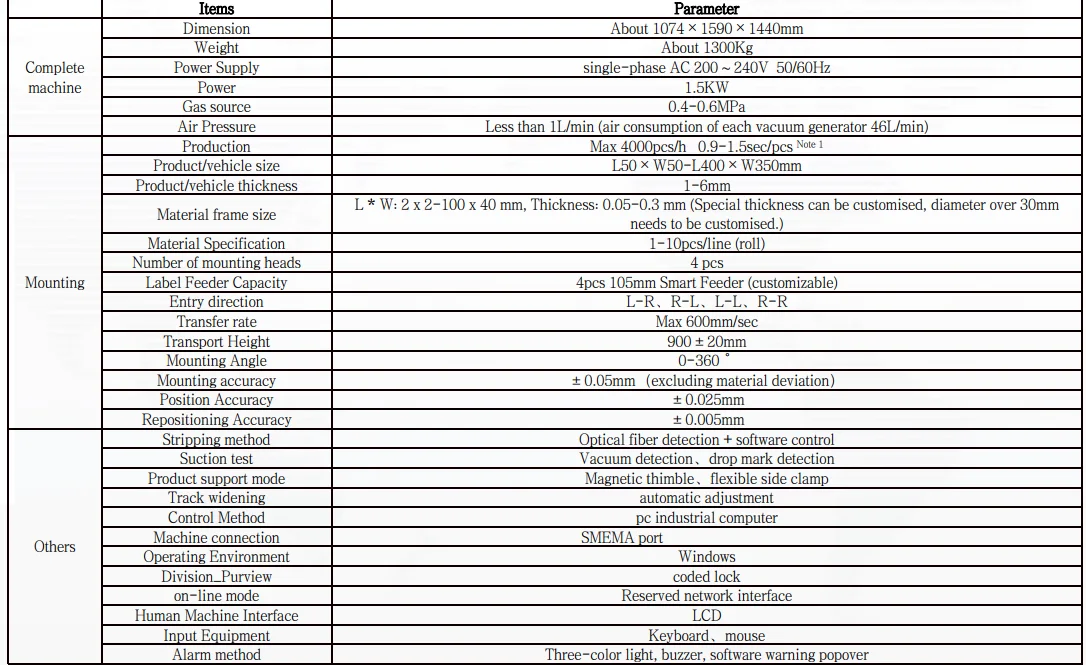

T2D Parameter

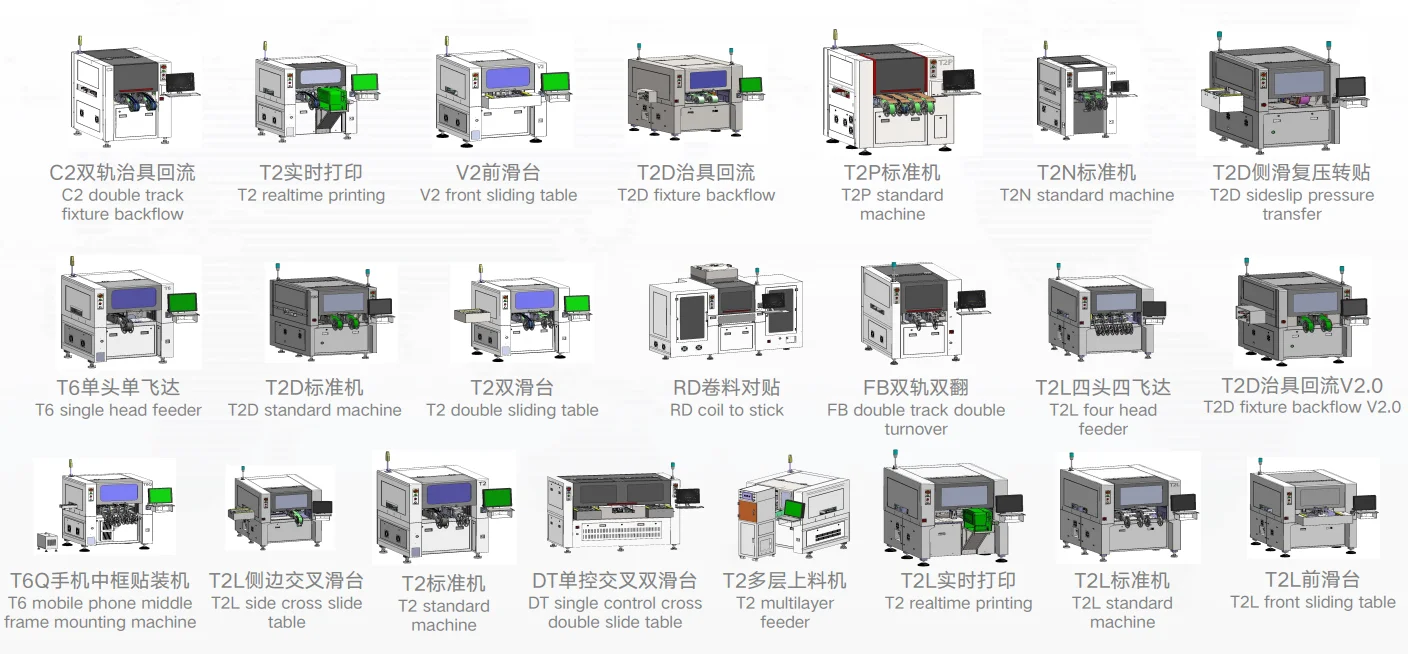

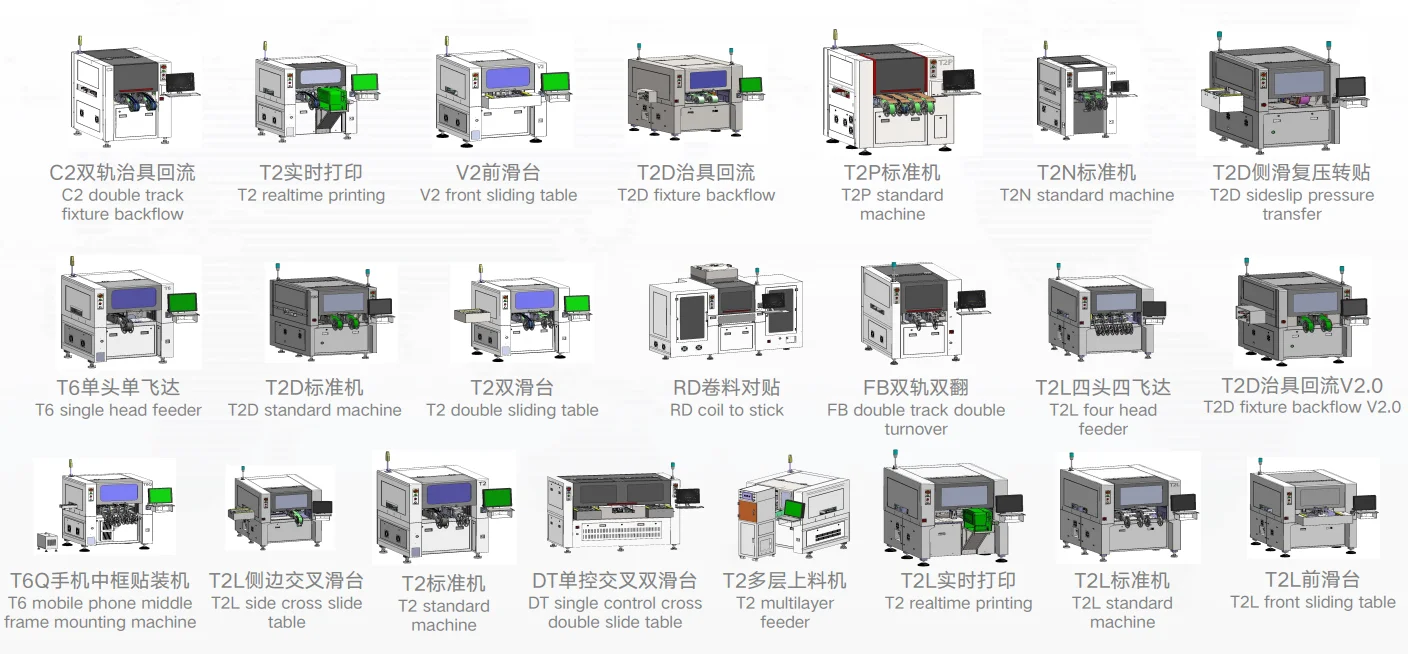

Products Series

Mounting Head

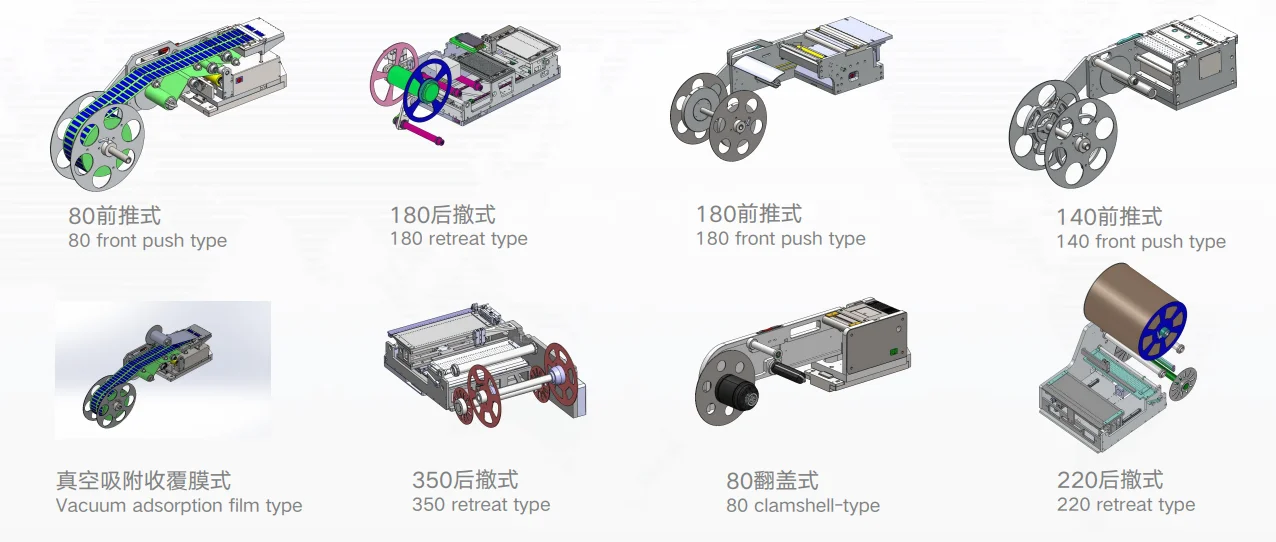

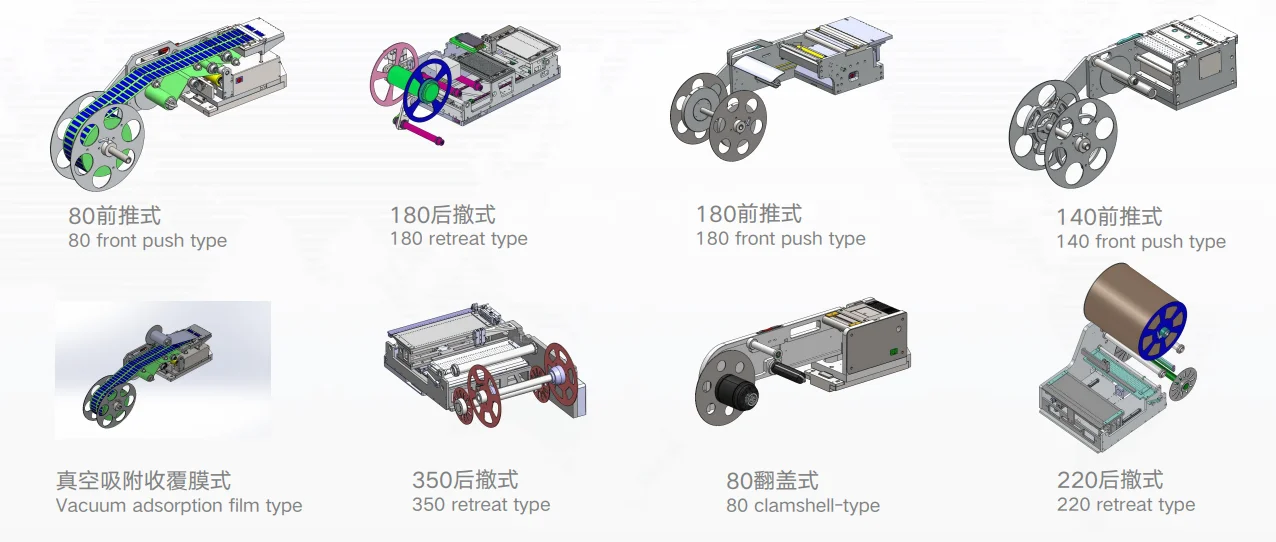

Feeder

The most professional types and models of feeder in the industry can be compatible with almost all the material requirements of 1-350mm in the mounting industry.

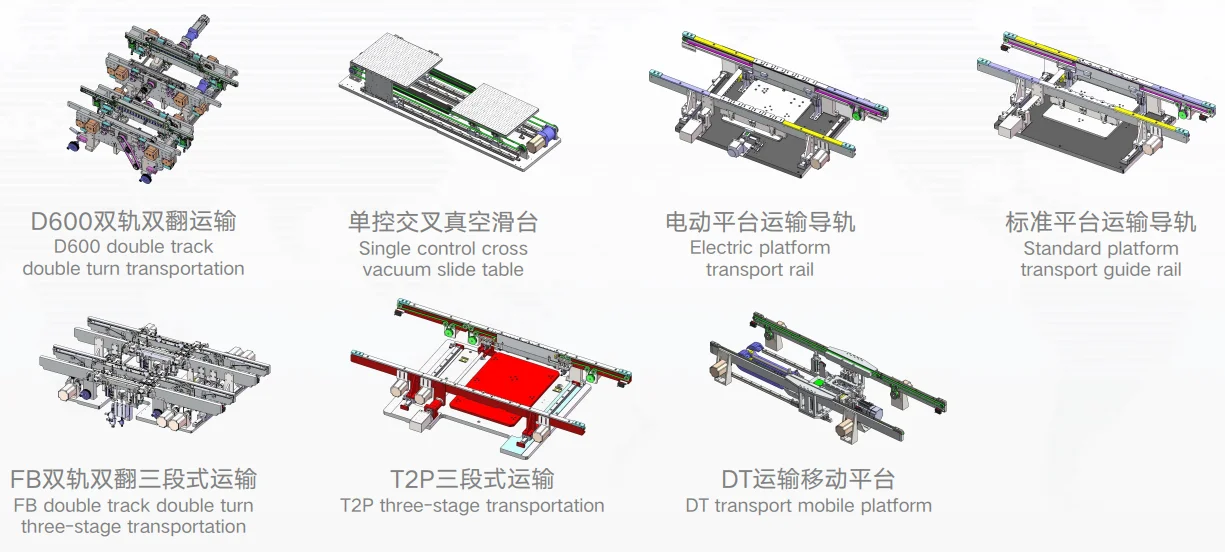

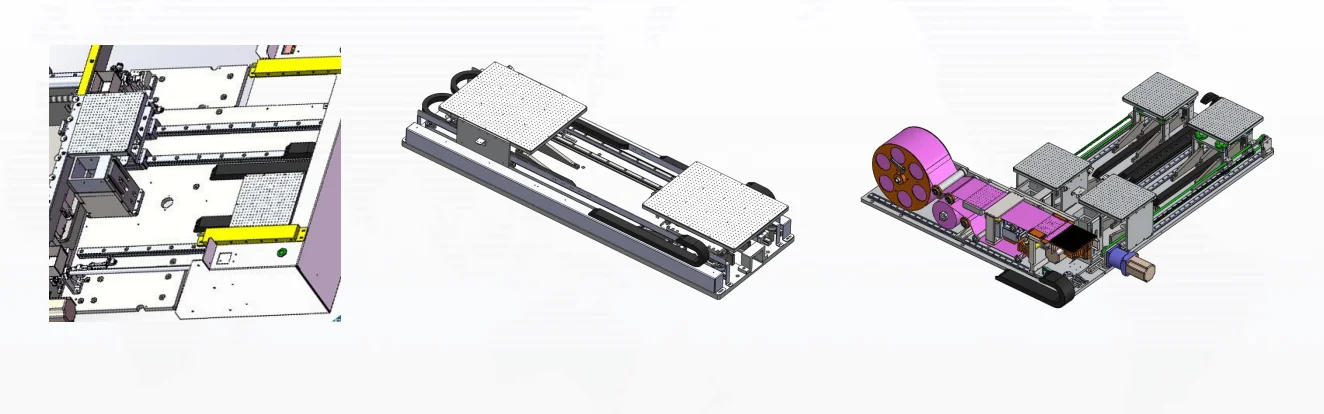

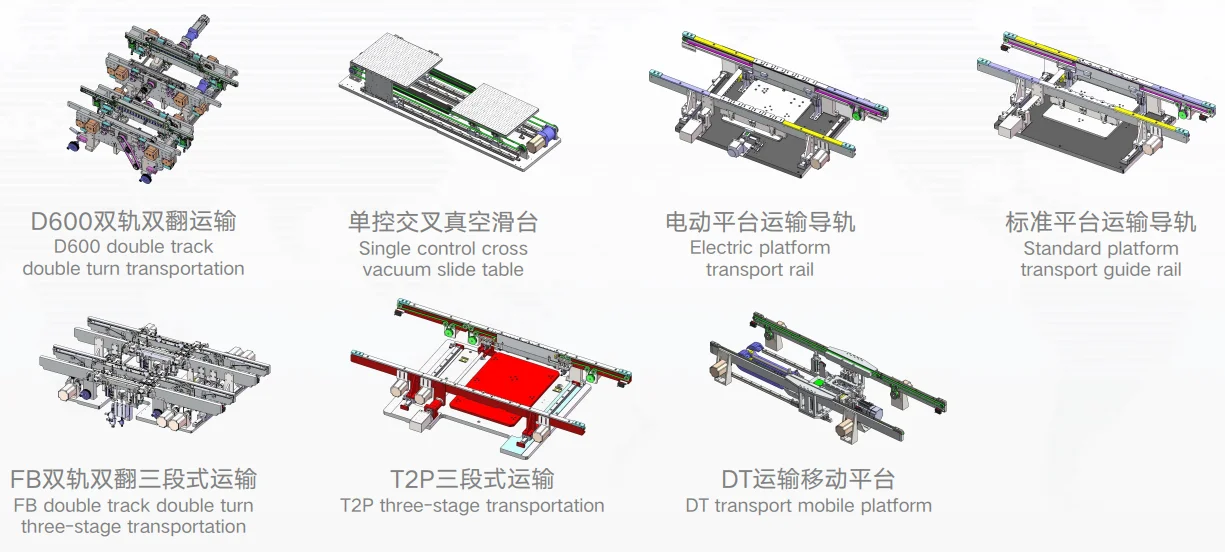

Mode of transportation

Multiple transportation solutions can flexibly support the transportation needs of various products.

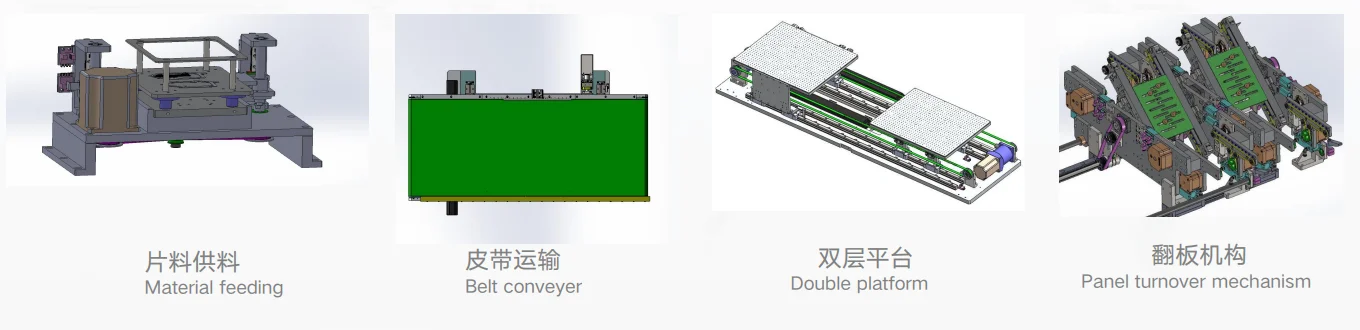

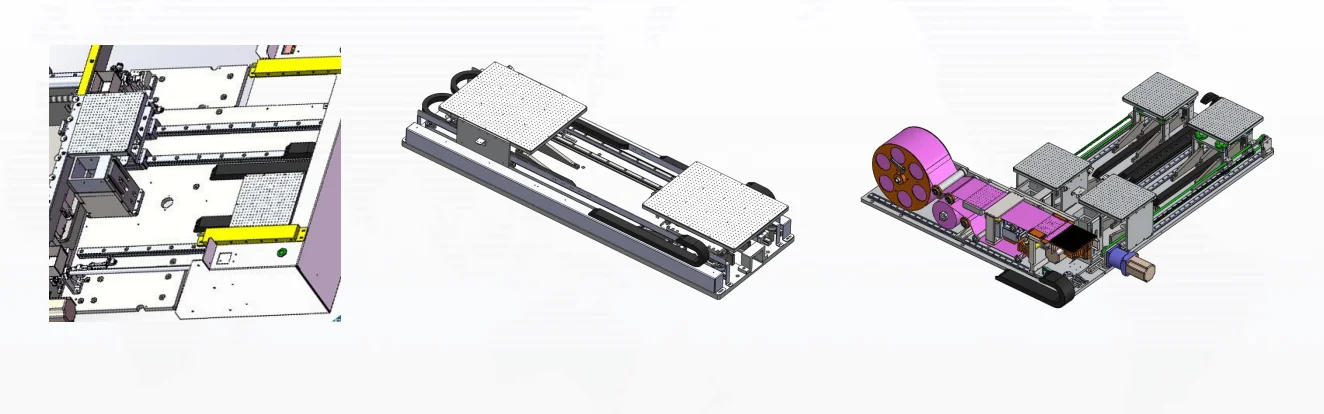

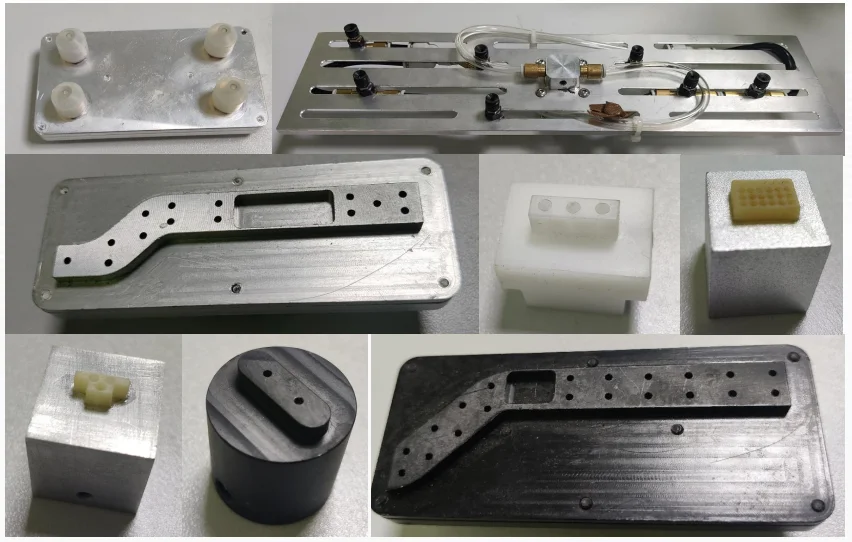

Feeding Platform

Provide flexible and reliable solutions for materials that cannot be made into coils.

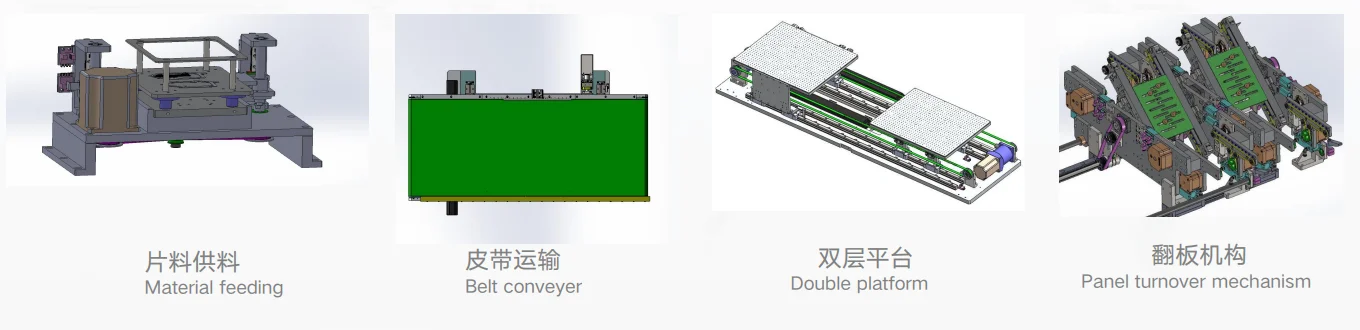

Customized Product

The equipment can be customized according to customer's actual requirements to meet the ever-changing

needs of customers, such as;

1.Tray plate feeding

2.Automatic loading and unloading machine

3.Material feeding

4.Belt conveyer

5.Platform conveyer

6.Flip plate and other special requirements

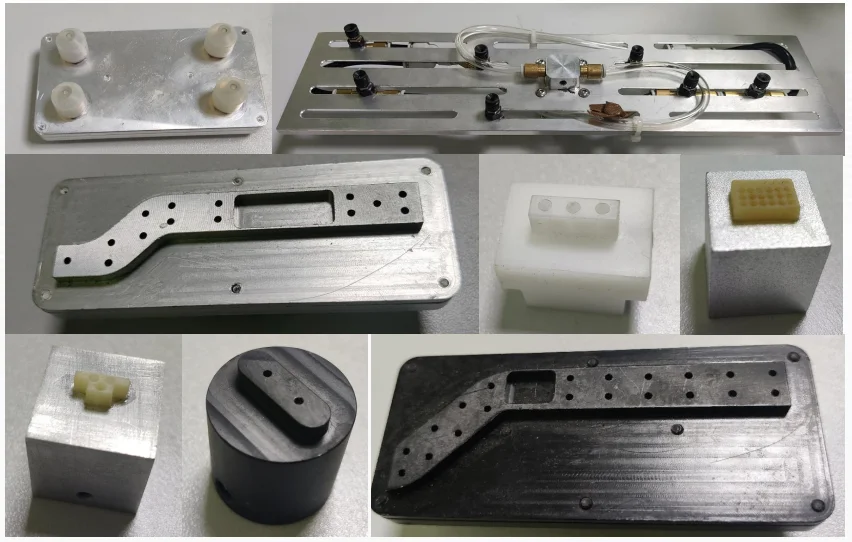

Suction Nozzle

A variety of nozzle solutions are compatible with the mounting requirements of various products in the industry.

Quality Assurance

Laser interferometer:The motion accuracy of each equipment will be tested and compensated by the British RENISHAW laser interferometer to ensure that the mounting accuracy can reach ±0.05mm.

The RENISHAW laser interferometer has a precision resolution of 0.0001mm.

Quadratic element:The motion accuracy of each equipment after debugging will be tested and calculated CPK by quadratic element to ensure the mounting accuracy.

The precision resolution of the quadratic element is 0.001mm.

Quality Assurance

After the equipment is installed, laser interferometer, quadratic element and other instruments are used for accuracy detection and correction, and then 72-hour aging test and actual production test are carried out. Only after all tests meet the requirements, the equipment can be deliveried.

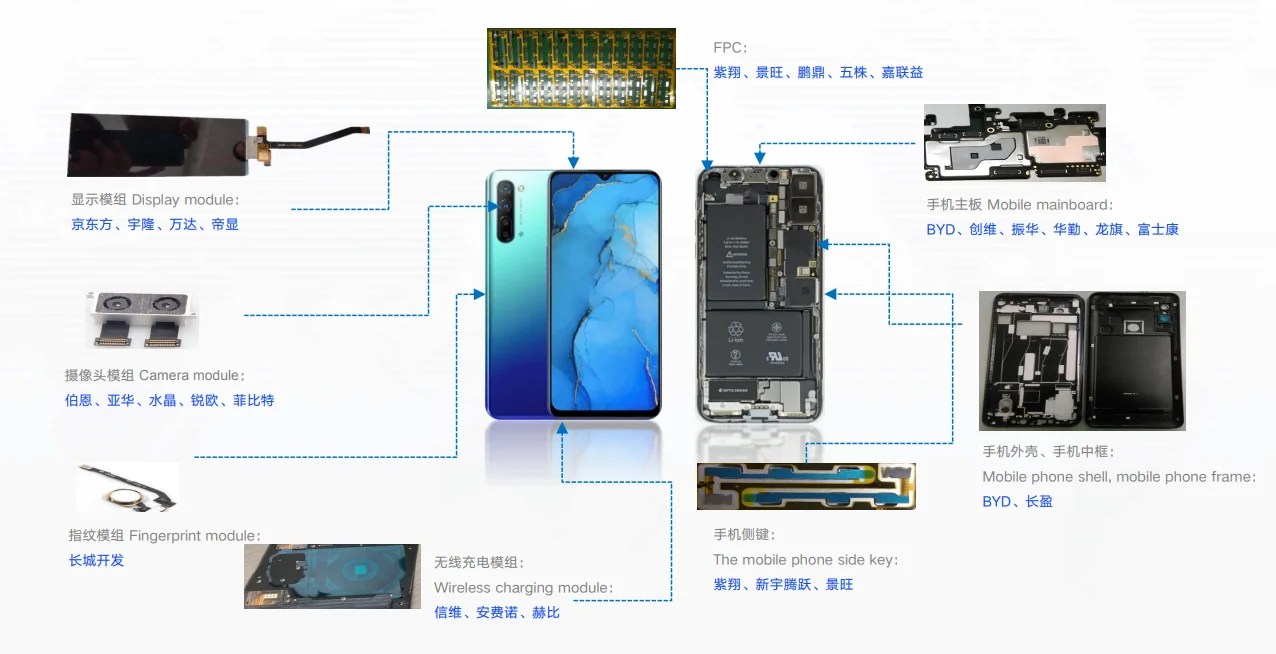

Application

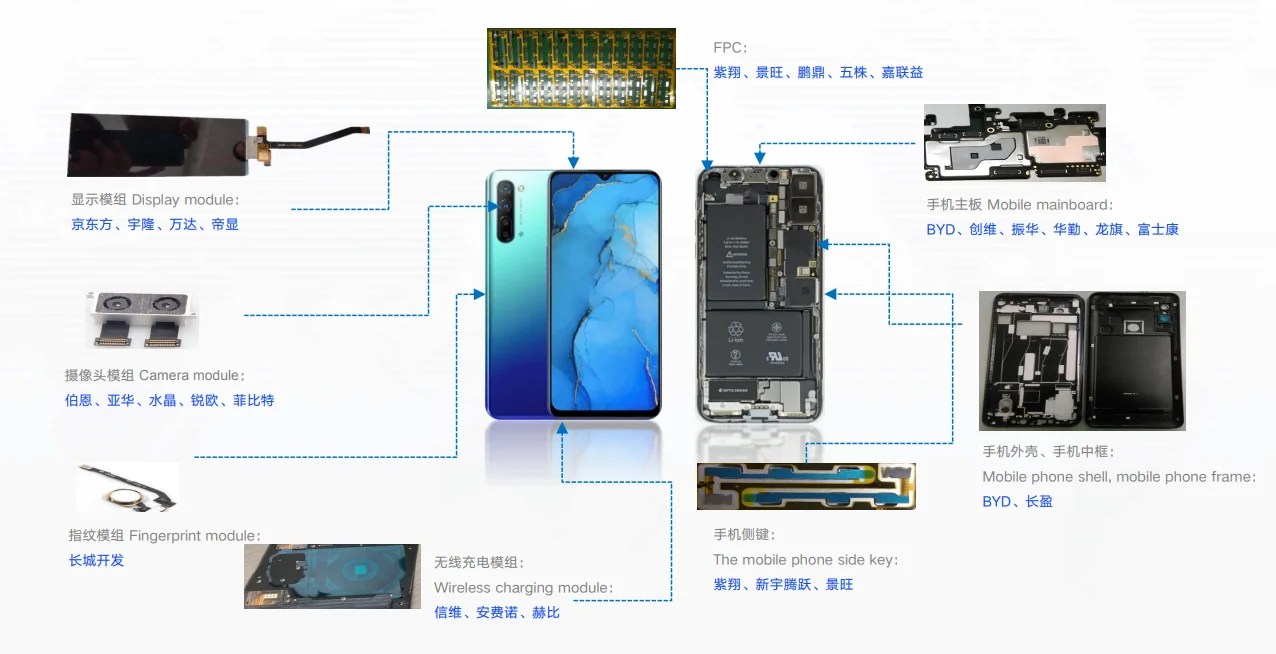

Cellphone Application

Production equipment - Excellent architecture)

1.Frame: High precision and stable structure integrated frame to ensure stability for high speed mounting work.

2.Electric cabinet: Safe and convenient drawer type design, compared with the built-in electronic control structure is easier to maintain and clean. Visual electronic control component design of the equipment is easy to manage by maintenance personnel, eliminate electronic control risks timely, improve the safety of the machine and prolong its service life.

3.The equipment uses silent vacuum pump with low noise and stable negative pressure source. The air source consumption of our equipment is as low as 1L/Min, which is far less than the other machines using vacuum generator (air source consumption is more than 100L/Min), and save the air source consumption for customers on the production site. If the gas source consumption is too large, the load of the air compressor in the factory will be increased, and if it is serious, the pressure of the production line will be unstable and the production will be affected.

4.Beam: Natural marble material, after grinding processing, the straightness error of guide rail assembly of the equipment can be controlled within 5 microns, to ensure the high precision requirements, the long-term operation and not easy to deformation.

T2Parameter

T2D Parameter

Products Series

Mounting Head

Feeder

The most professional types and models of feeder in the industry can be compatible with almost all the material requirements of 1-350mm in the mounting industry.

Mode of transportation

Multiple transportation solutions can flexibly support the transportation needs of various products.

Feeding Platform

Provide flexible and reliable solutions for materials that cannot be made into coils.

Customized Product

The equipment can be customized according to customer's actual requirements to meet the ever-changing

needs of customers, such as;

1.Tray plate feeding

2.Automatic loading and unloading machine

3.Material feeding

4.Belt conveyer

5.Platform conveyer

6.Flip plate and other special requirements

Suction Nozzle

A variety of nozzle solutions are compatible with the mounting requirements of various products in the industry.

Quality Assurance

Laser interferometer:The motion accuracy of each equipment will be tested and compensated by the British RENISHAW laser interferometer to ensure that the mounting accuracy can reach ±0.05mm.

The RENISHAW laser interferometer has a precision resolution of 0.0001mm.

Quadratic element:The motion accuracy of each equipment after debugging will be tested and calculated CPK by quadratic element to ensure the mounting accuracy.

The precision resolution of the quadratic element is 0.001mm.

Quality Assurance

After the equipment is installed, laser interferometer, quadratic element and other instruments are used for accuracy detection and correction, and then 72-hour aging test and actual production test are carried out. Only after all tests meet the requirements, the equipment can be deliveried.

Application

Cellphone Application

Website:https://www.pcbcuttingmachine.com

Contacts:Eva Liu +8613450659407 +8613416743702

Tel:+86-512-62751429

Skype:evaliuhuan

Email:caojun@hk-yush.com sales@yushunli.com evaliu@hk-yush.com

Address: Building H, GuoRui Pioneering Park,

No. 1068 Jinyang East Road, Lujia Town, Kunshan,Suzhou.

Postcode:215331

Dongguan Factory Address: 5th Floor, No.10,

Shanquan Road, Yongtou Village, Chang’an Town,

Dongguan City, Guangdong province, China.

Postcode:523843