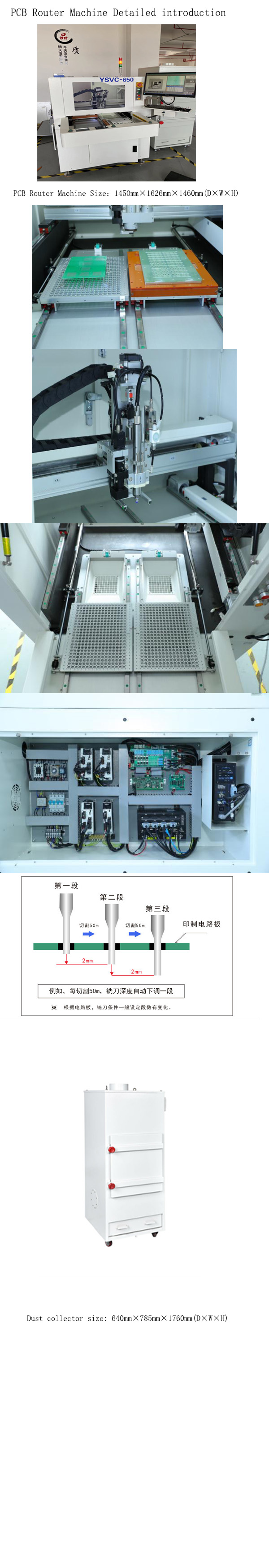

Automatic PCB Router Machine - YSVC-600

Specification:

|

<span style="font-size:15.0pt;font-family:"color:black;">YSVC-600- |

|

|

Host + dust collector weight |

800 KG |

|

Machine size: |

1075mm×1430mm×1460mm(D×W×H) |

|

Cutting accuracy: |

±0.08mm |

|

Splitting stress value: |

below 300uε |

|

Dust collector power |

3HP (option 5HP) |

|

NSK spindle speed: |

Max.60,000rpm |

|

CCD camera calibration accuracy: |

±0.01mm |

|

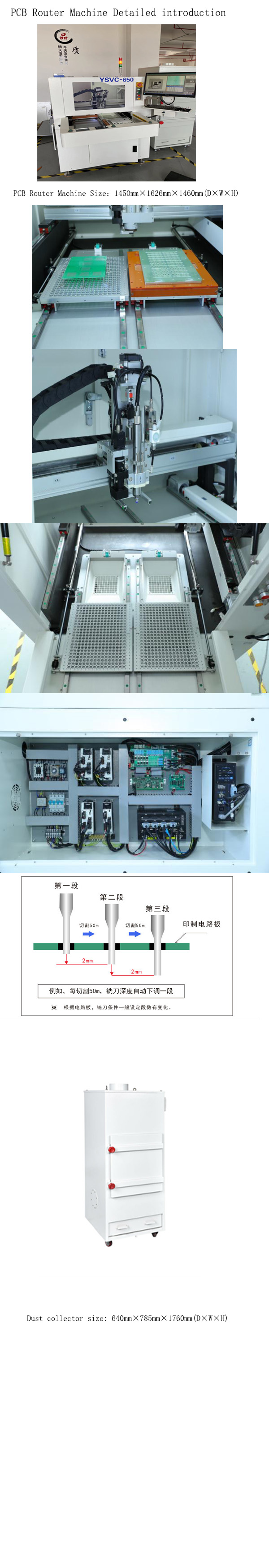

Dust collection cabinet size: |

640mm×785mm×1760mm(D×W×H) |

|

X-Y AC Servo speed: |

0-1000mm/sec |

|

Tool diameter: |

0.8-2.3mm |

|

X-Y repeatability: |

±0.02mm |

|

Unilateral working size: |

290mm X 350mm |

|

Four-axis servo drive: |

X, Y1, Y2, Z |

|

Z AC Servo Speed: |

0-800mm/sec |

|

PCB board cutting thickness: |

0.2mm-6.0mm |

1. Automatic PCB Router Machine adopts High-speed NSK spindle to cut and Depaneling, which greatly reduces the Cutting stress, has high precision, small inertia and fast response.

2. Grating safety facilities are installed in the PCB pick-and-place area of the double Y-axis worktable to avoid manual misoperation and meet public safety requirements.

3.The window operation interface is friendly to switch between Chinese and English, and the window operation interface is shown in the figure. The editing program is simple and can quickly complete the multi-point program.

4.Multi-layer management authority of software users to prevent misuse and other behaviors.

5.Automatic PCB Router Machine The vacuuming under the fully adopts a sealed design, and the suction port adopts a 45-degree oblique angle to reduce the eddy current generated by the dust inside.

6. The upper vacuuming structure (optional) adopts electrostatic brush to seal the cutting point, and independently vacuums the single cutting point, which greatly improves the vacuuming effect.

7.The milling cutter detection system adopts a photoelectric sensor to monitor the milling cutter status in real time, effectively preventing the phenomenon of continuing operation after the cutter is broken.

8.The software sets the milling cutter segmentation function, automatically lowers the cutter compensation, prolongs the service life of the milling cutter and reduces the cost.

Automatic PCB Router Machine - YSVC-600

Specification:

|

<span style="font-size:15.0pt;font-family:"color:black;">YSVC-600- |

|

|

Host + dust collector weight |

800 KG |

|

Machine size: |

1075mm×1430mm×1460mm(D×W×H) |

|

Cutting accuracy: |

±0.08mm |

|

Splitting stress value: |

below 300uε |

|

Dust collector power |

3HP (option 5HP) |

|

NSK spindle speed: |

Max.60,000rpm |

|

CCD camera calibration accuracy: |

±0.01mm |

|

Dust collection cabinet size: |

640mm×785mm×1760mm(D×W×H) |

|

X-Y AC Servo speed: |

0-1000mm/sec |

|

Tool diameter: |

0.8-2.3mm |

|

X-Y repeatability: |

±0.02mm |

|

Unilateral working size: |

290mm X 350mm |

|

Four-axis servo drive: |

X, Y1, Y2, Z |

|

Z AC Servo Speed: |

0-800mm/sec |

|

PCB board cutting thickness: |

0.2mm-6.0mm |

1. Automatic PCB Router Machine adopts High-speed NSK spindle to cut and Depaneling, which greatly reduces the Cutting stress, has high precision, small inertia and fast response.

2. Grating safety facilities are installed in the PCB pick-and-place area of the double Y-axis worktable to avoid manual misoperation and meet public safety requirements.

3.The window operation interface is friendly to switch between Chinese and English, and the window operation interface is shown in the figure. The editing program is simple and can quickly complete the multi-point program.

4.Multi-layer management authority of software users to prevent misuse and other behaviors.

5.Automatic PCB Router Machine The vacuuming under the fully adopts a sealed design, and the suction port adopts a 45-degree oblique angle to reduce the eddy current generated by the dust inside.

6. The upper vacuuming structure (optional) adopts electrostatic brush to seal the cutting point, and independently vacuums the single cutting point, which greatly improves the vacuuming effect.

7.The milling cutter detection system adopts a photoelectric sensor to monitor the milling cutter status in real time, effectively preventing the phenomenon of continuing operation after the cutter is broken.

8.The software sets the milling cutter segmentation function, automatically lowers the cutter compensation, prolongs the service life of the milling cutter and reduces the cost.

Website:https://www.pcbcuttingmachine.com

Contacts:Eva Liu +8613450659407 +8613416743702

Tel:+86-512-62751429

Skype:evaliuhuan

Email:caojun@hk-yush.com sales@yushunli.com evaliu@hk-yush.com

Address: Building H, GuoRui Pioneering Park,

No. 1068 Jinyang East Road, Lujia Town, Kunshan,Suzhou.

Postcode:215331

Dongguan Factory Address: 5th Floor, No.10,

Shanquan Road, Yongtou Village, Chang’an Town,

Dongguan City, Guangdong province, China.

Postcode:523843